Our immersion systems lead the industry in productivity, imaging and overlay performance for high-volume manufacturing of the most advanced Logic and Memory chips.

Immersion systems

Immersion systems are the workhorses of the industry. Our latest NXT machines have shown the ability to run in excess of 6,000 wafers per day, with an average five percent productivity increase over 12 months, supporting our customers' value requirements. We continue to innovate our immersion systems to meet the requirements of future nodes, benefiting from commonalities in R&D with our EUV program, while ensuring the platform’s extendibility through System Node Enhancement Package upgrades. Thanks to these packages, any NXT system can be upgraded to the latest technology.

TWINSCAN NXT:2150i

TWINSCAN NXT:2150iThe dual-stage ArF immersion lithography system offers better overlay and imaging performance at higher productivity and with less process complexity.

TWINSCAN NXT:2100i

TWINSCAN NXT:2100iThe TWINSCAN NXT:2100i is a dual-stage immersion lithography tool equipped with a new projection-optics adjustment system that improves overlay.

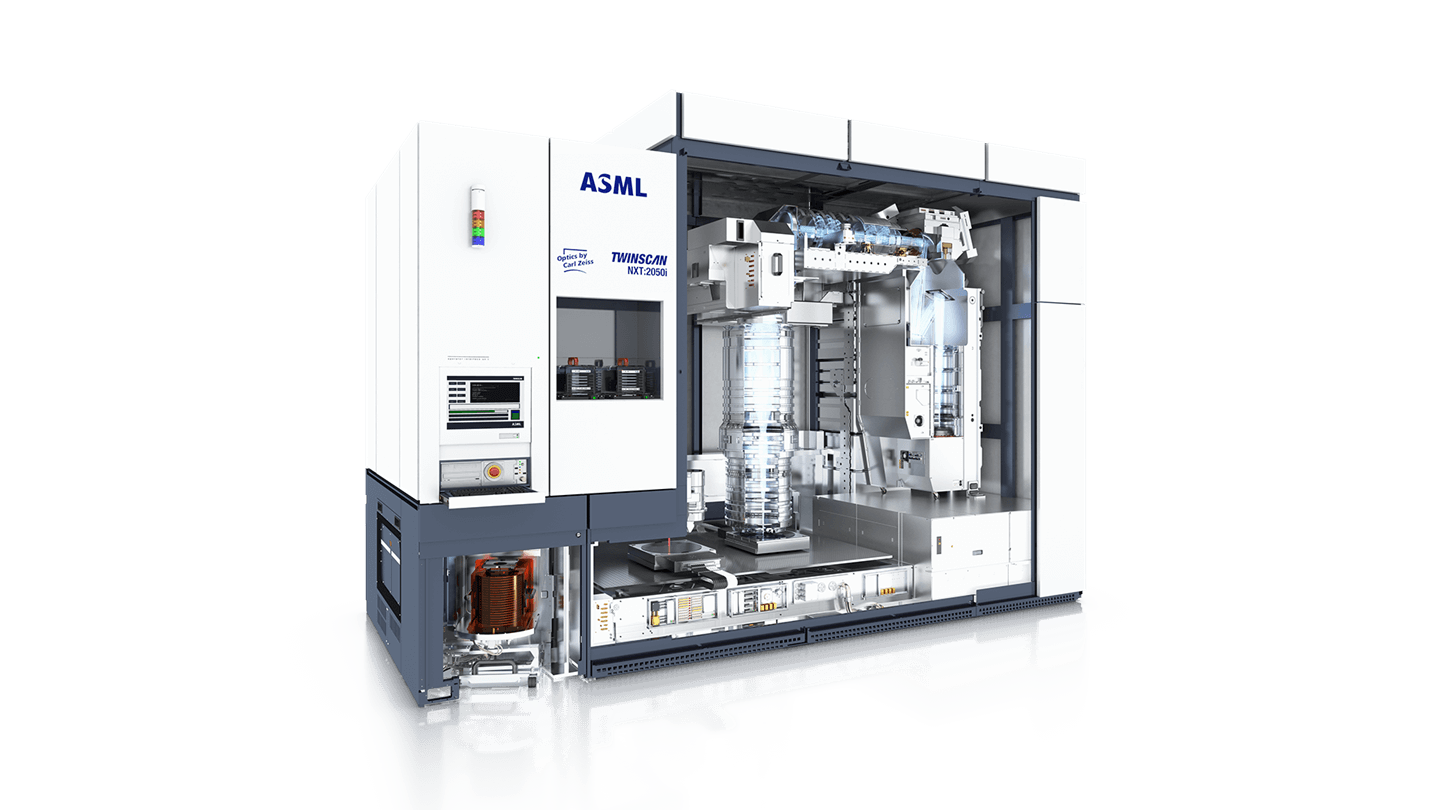

TWINSCAN NXT:2050i

TWINSCAN NXT:2050iThe TWINSCAN NXT:2050i is a high-productivity, dual-stage immersion lithography tool designed for volume production of 300 mm wafers at advanced nodes.

TWINSCAN NXT:2000i

TWINSCAN NXT:2000iThe TWINSCAN NXT:2000i delivers outstanding overlay, focus control and cross-matching for high-volume manufacturing of advanced Logic and DRAM nodes.

TWINSCAN NXT:1980Fi

TWINSCAN NXT:1980FiThe TWINSCAN NXT:1980Fi is a dual-stage ArF immersion lithography system that prints mid-critical layers on 300 mm wafers with industry-leading throughput.

Dry systems

Chips are made up of many layers stacked on top of one another, and it’s not necessarily the latest and greatest immersion lithography machines that are used to produce these layers. In a given chip, there may be one or two more complicated layers that are made using an EUV lithography machine, but the rest can often be printed using ‘older’ technology such as dry lithography systems. This is certainly more cost-effective for customers, since these older machines are less expensive to purchase and maintain. Read about how dry lithography systems are enabling progress.

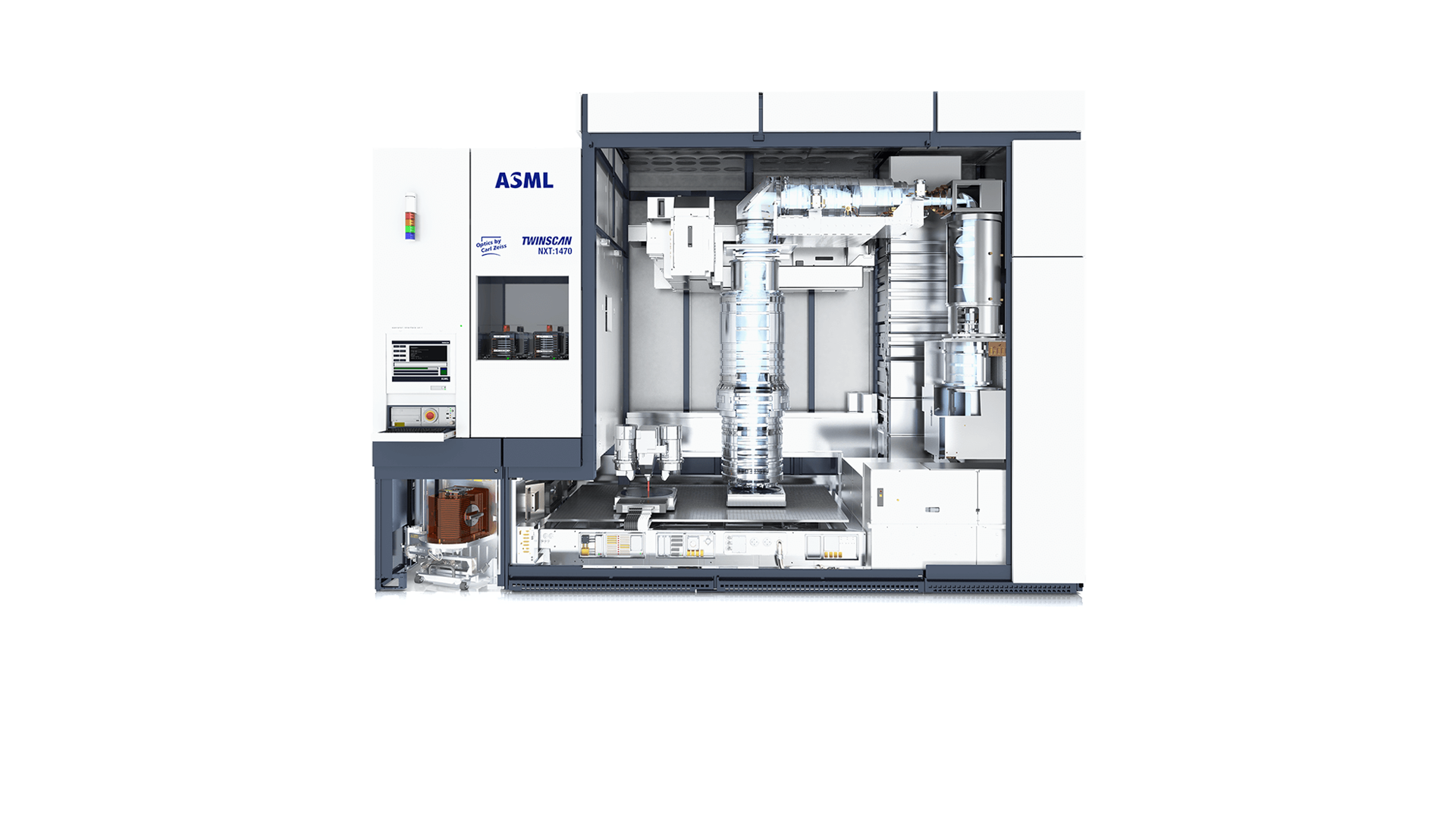

TWINSCAN NXT:1470

TWINSCAN NXT:1470The industry’s most productive lithography platform yet is the first to go beyond 300 wafers per hour.

TWINSCAN XT:1460K

TWINSCAN XT:1460KA high-productivity dry ArF lithography tool with excellent overlay and imaging performance for volume production at 65 nm resolution.

TWINSCAN XT:1060K

TWINSCAN XT:1060KASML’s most advanced KrF (krypton fluoride) laser 'dry' lithography system.

TWINSCAN NXT:870B

TWINSCAN NXT:870BThe dual-stage KrF dry lithography system exposes 300 mm wafers with an industry-first throughput of 400 wafers per hour.

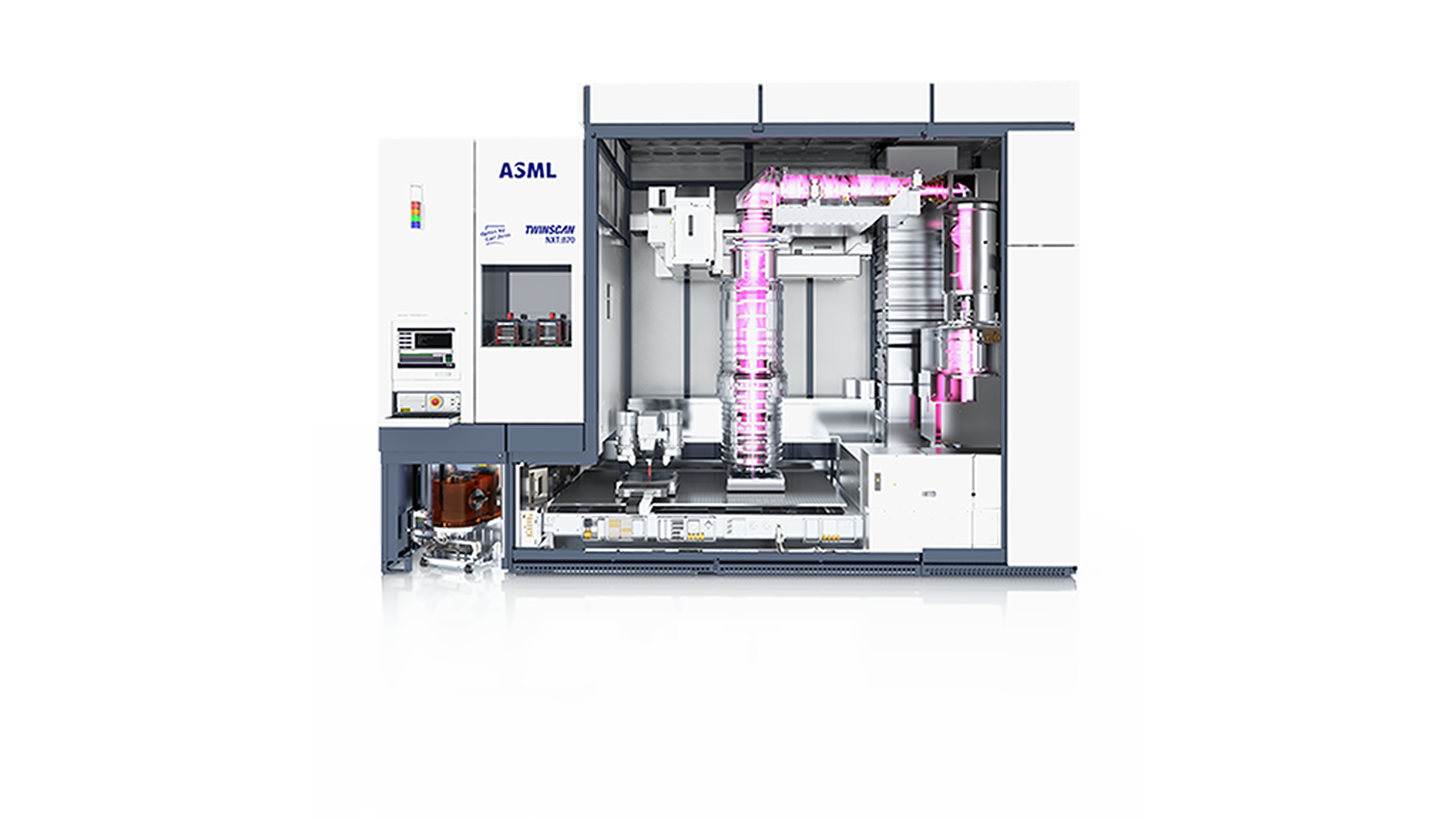

TWINSCAN NXT:870

TWINSCAN NXT:870This machine uses the latest NXT platform for volume 300 mm wafer production at and below 110 nm resolution.

TWINSCAN XT:860N

TWINSCAN XT:860NDesigned using state-of-the-art optics for volume 200 and 300 mm wafer production at and below 110 nm resolution.

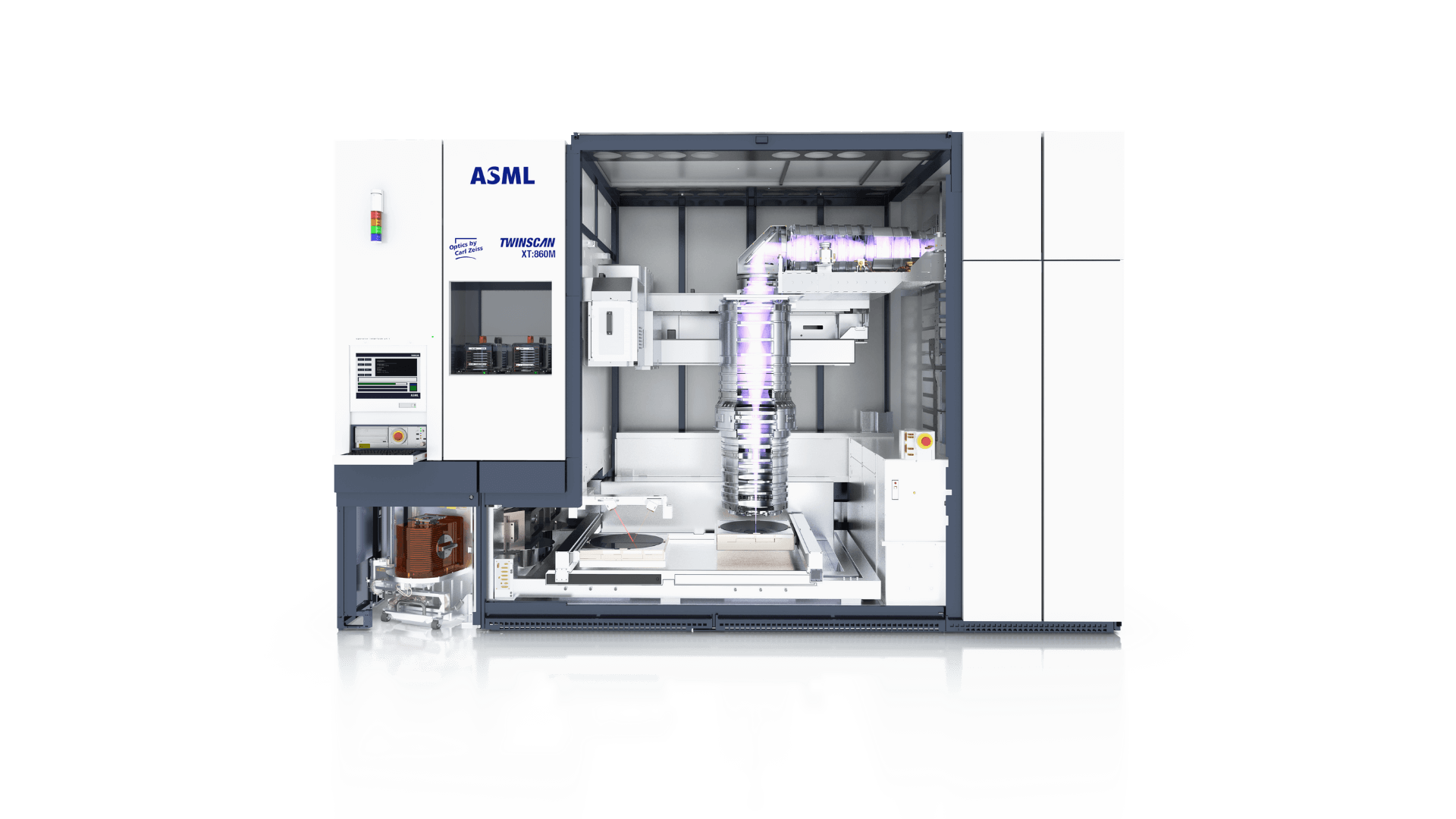

TWINSCAN XT:860M

TWINSCAN XT:860MDesigned for volume 300 mm wafer production at and below 110 nm resolution.

TWINSCAN XT:400M

TWINSCAN XT:400MThe dual-stage i-line dry lithography system prints 200 mm and 300 mm wafers with ≤ 20 nm overlay across the entire wafer.

Continuing innovation

We continue to innovate in productivity, cost of ownership and performance across our TWINSCAN XT product lines (ArF, KrF and i-line), for both 200 mm and 300 mm wafer sizes. With 3D NAND Memory becoming mainstream, ASML has developed a broad portfolio of options for all dry systems, able to address the specific challenges of this technology, including high-topography layer stacks and wafer warpage, among others.

In 2016, due to the strong growth in IoT, automotive and industrial markets, we introduced a 200 mm version of the TWINSCAN XT scanners, which not only helps to increase the output of customer fabs, but is also used to replace aging lithography equipment in existing 200 mm fabs.

How immersion lithography saved Moore’s Law

Find out how immersion lithography triggered a paradigm shift in chip manufacturing.