KrF light source

Resolution

Projection lens

Wafers per hour

Key features & benefits

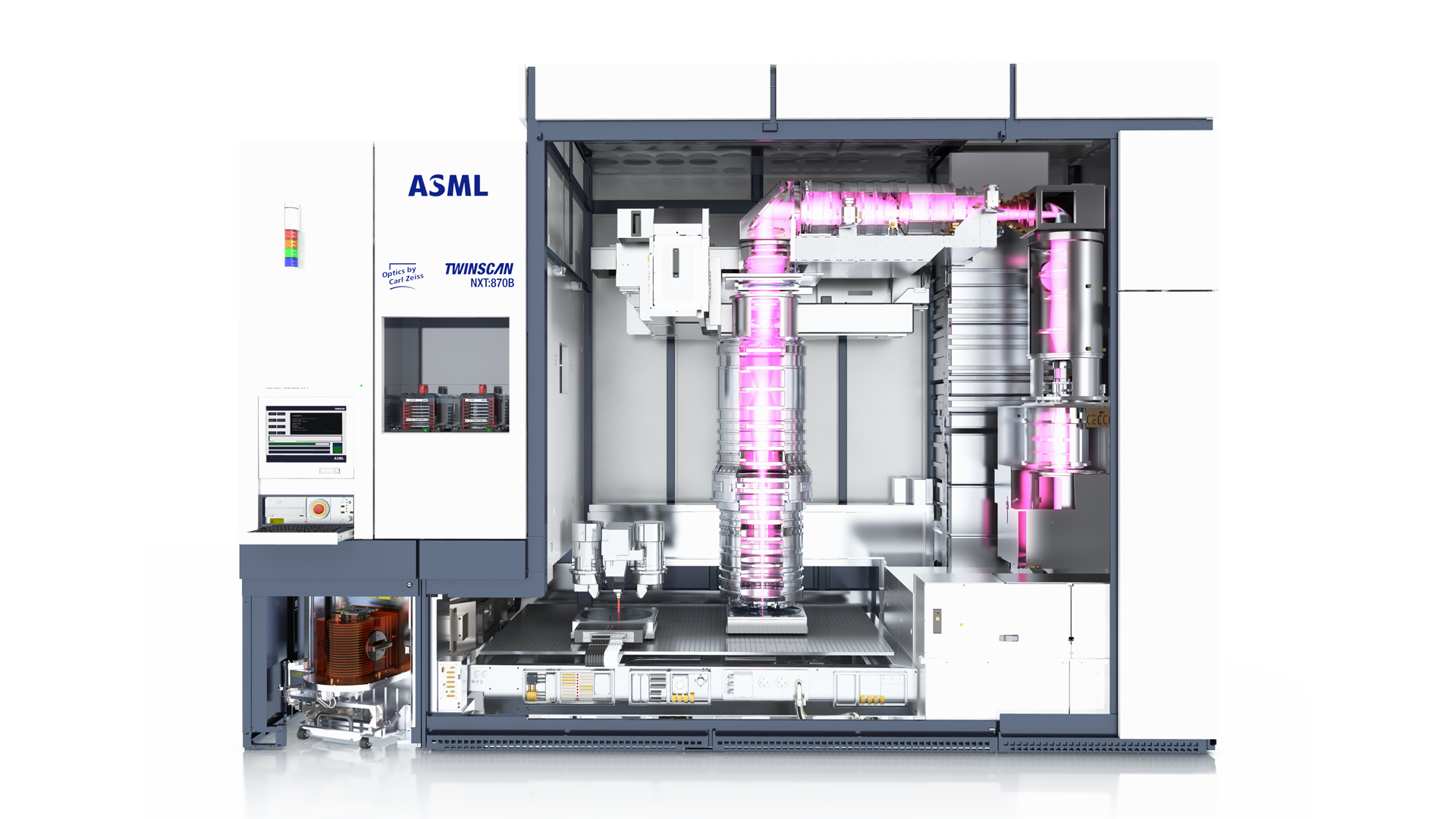

The TWINSCAN NXT:870B is the successor to the NXT:870. Innovative optics and mechatronics improvements enable the system to offer 20% higher throughput while maintaining overlay and imaging performance.

The NXT:870B lowers chipmakers’ cost per wafer exposure and maximizes the value that they can get out of the space in their fabs. KrF lithography systems are industry workhorses that enable chips in multiple market segments, and with its higher throughput, the NXT:870B will enable chipmakers to cost efficiently continue their technology and capacity roadmaps.

Like its predecessor, the NXT:870B uses KrF technology on the same NXT platform used for ArF dry and immersion scanners. This improves overlay by facilitating excellent alignment of chip layers printed using these different technologies.

Faster stages, enabled by extending our mechatronics capabilities, were key to reaching 400 wafers per hour. Innovative solutions were needed to maintain overlay and imaging performance at that speed. For example, the reticle – the blueprint of the chip layer being printed – can slip as it quickly moves back and forth. That’s why we added reticle ‘pushers’ that prevent slipping to maintain the system’s precise overlay.

The NXT:870B is equipped with our most advanced KrF lens, which comes with additional manipulators that correct for heating effects customers may encounter in critical process layers. Moreover, the additional manipulators pave the way for future options to fit customer-specific requirements in each respective market segment.