The building blocks of technology

It’s hard to imagine a world without microchips. They’re at the heart of the devices that we use to work, travel, stay fit and entertain ourselves – from cars to smartphones and from MRI scanners to industrial robots and data centers.

Microchips are everywhere. In 2021, semiconductor unit sales reached a record 1.15 trillion-unit shipments, and in 2022, global semiconductor industry sales topped €573.5 billion. By delivering new functionalities, better performance and lower cost with each generation, advances in chips have spawned new products and transformed industries.

*Data source: WSTS

What’s a microchip?

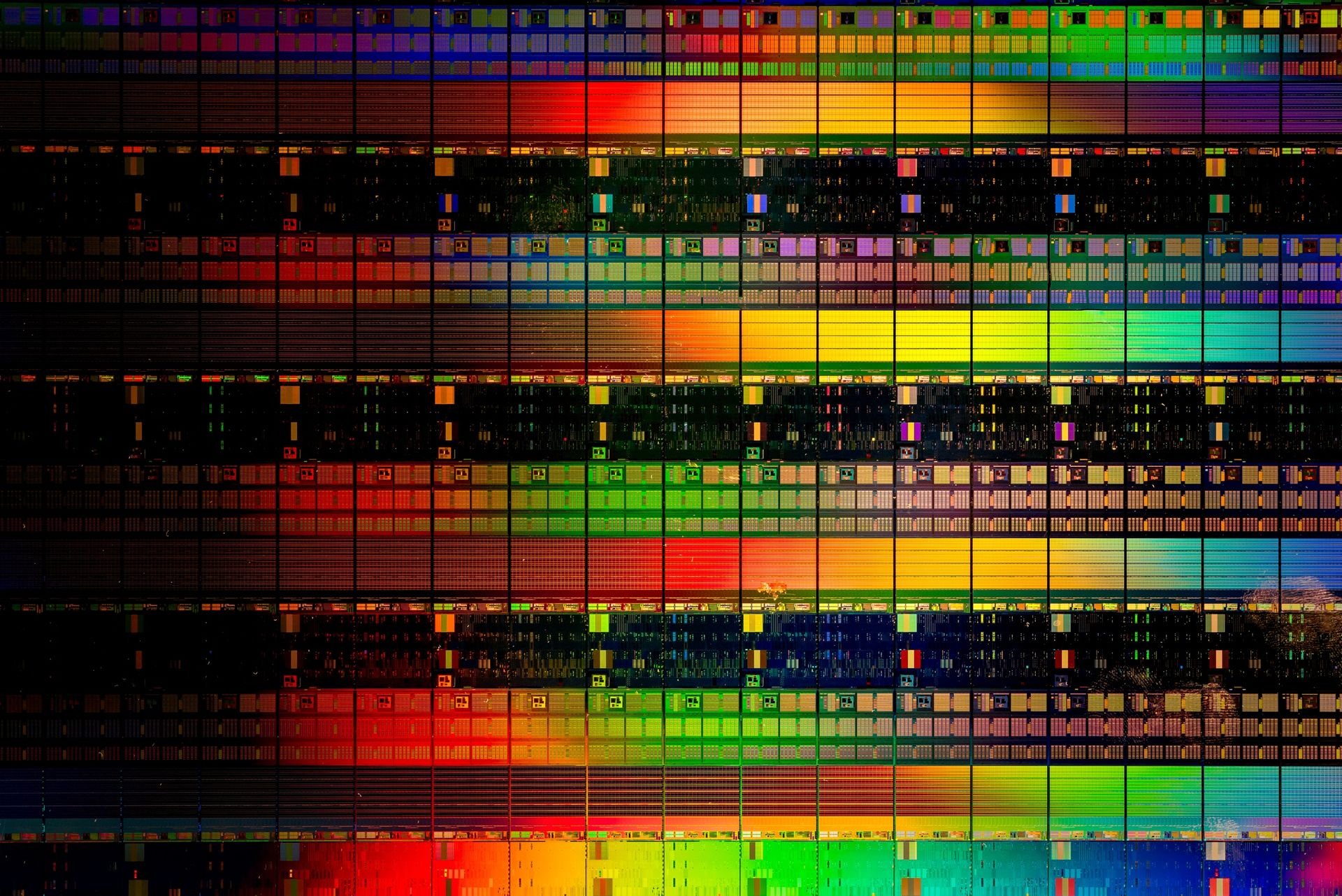

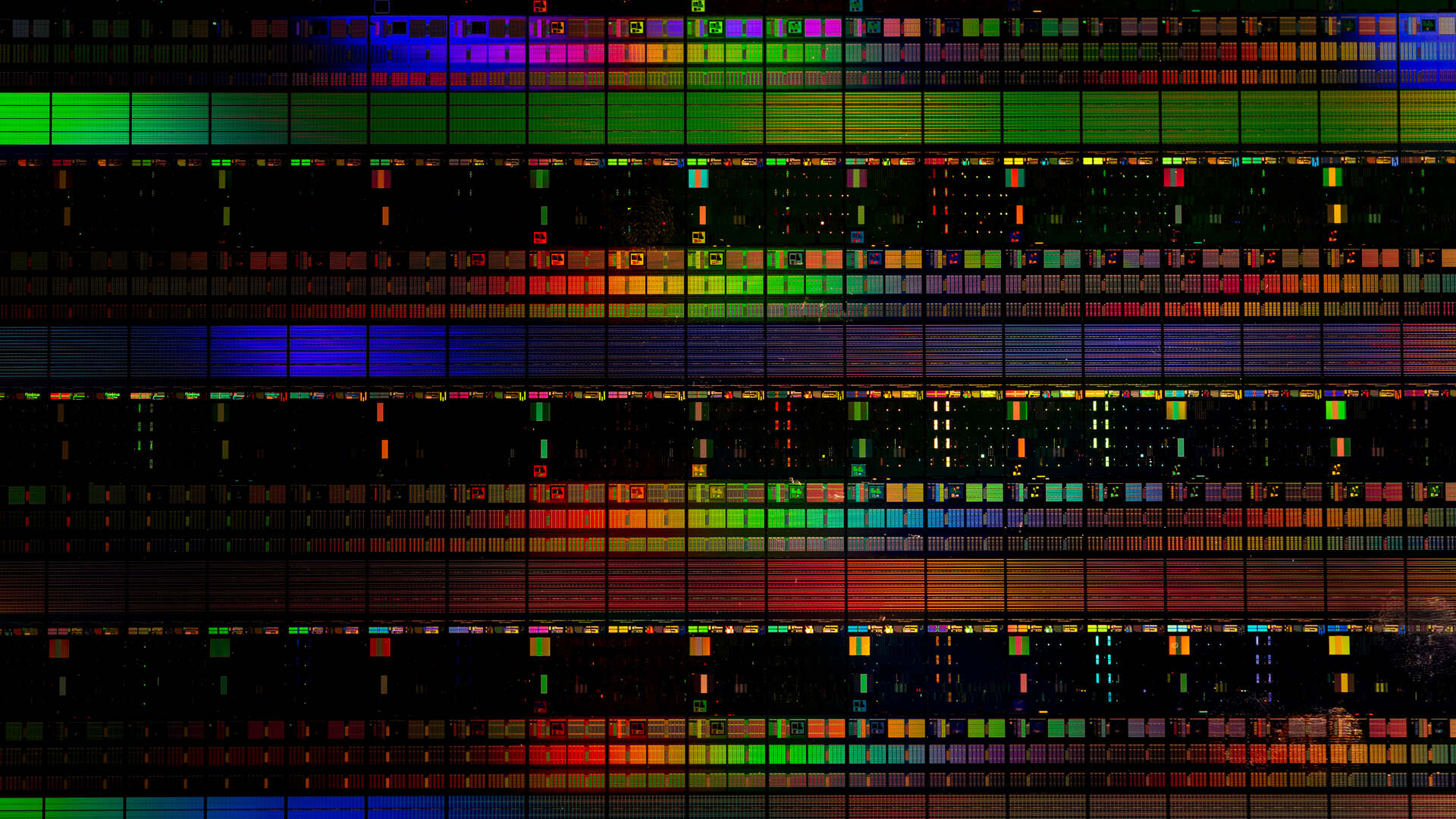

A microchip (also called a chip, a computer chip, an integrated circuit or IC) is a set of electronic circuits on a small flat piece of silicon. On the chip, transistors act as miniature electrical switches that can turn a current on or off. The pattern of tiny switches is created on the silicon wafer by adding and removing materials to form a multilayered latticework of interconnected shapes.

Digital gold

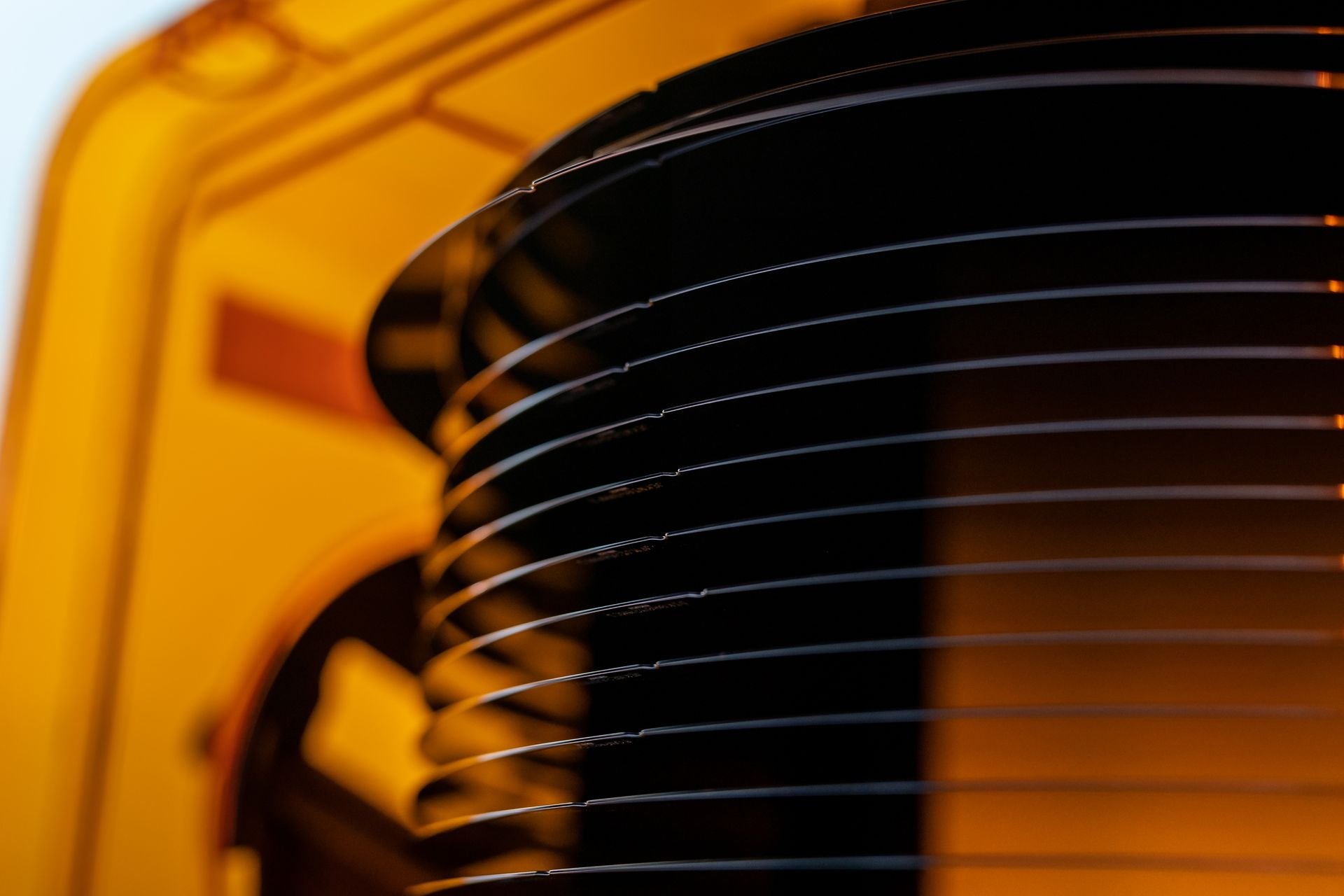

Silicon is the material of choice in the chip industry. Unlike the metals normally used to conduct electrical currents, silicon is a ‘semiconductor’, meaning that its conductive properties can be increased by mixing it with other materials such as phosphorus or boron. This makes it possible to turn an electrical current on or off.

The good news is that it’s everywhere! Silicon is made from sand, and it is the second most abundant element on earth after oxygen. Silicon wafers are made using a type of sand called silica sand, which is made of silicon dioxide. The sand is melted and cast in the form of a large cylinder called an ‘ingot’. This ingot is then sliced into thin wafers.

The nano scale

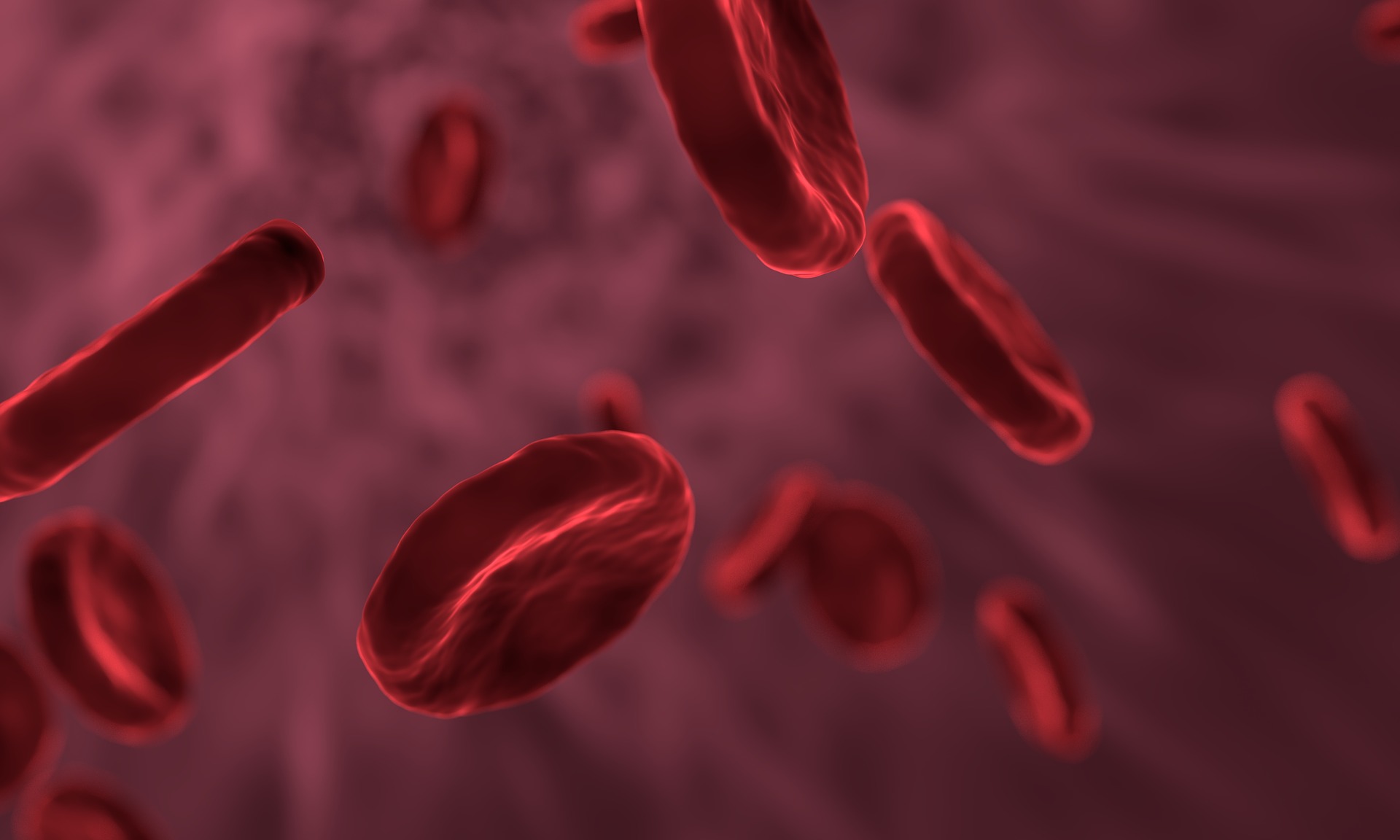

A microchip the size of your fingernail contains billions of transistors, so it’s easy to understand just how small the features on a chip need to be. Chip features are measured in nanometers. A nanometer is one billionth of a meter, or a millionth of a millimeter.

For comparison, a human red blood cell is 7,000 nanometers in diameter, and the flu virus is around 100 nanometers. The most advanced microchips contain features that are just a few dozen nanometers in size. ASML’s EUV (extreme ultraviolet) technology enables the scale of the smallest feature to be reduced even further. The smaller the features in the patterns that our systems can create, the more transistors manufacturers can fit on a chip, and the more the chip can do.

‘Flavors’ of chips

There are two major ways to categorize microchips: by functionality and by type of integrated circuitry. In terms of circuitry, a chip can be analog, digital, or mixed. The difference between analog and digital function has to do with the electric signals they process. In digital chips, the signals are binary. In analog chips, the signals are continuous, meaning they can take on any value within a given range, and they use more traditional circuit elements (resistors, capacitors and occasionally inductors).

In terms of functionality, there are four main categories: Logic chips, Memory chips, application-specific integrated chips (ASICs) and system-on-a-chip devices (SoCs). The two most common types of chips, Logic chips and Memory chips, are digital: they manipulate and store bits and bytes using transistors. ASICs and SoCs are mainly a mix of analog and digital.

Logic chips are the ‘brains’ of electronic devices – they process information to complete a task. Among Logic chips, CPUs (central processing units) are the ‘original’ chips, first designed in the 1960s. But there are also processors with specific functionality in mind, such as GPUs (graphical processing units, which are optimized for visual display) and NPUs (neural processing units, designed for deep and machine learning applications).

Memory chips store information. There are two types of Memory: volatile and non-volatile. Volatile Memory chips, such as DRAM (Dynamic Random Access Memory), are the ‘working memory’ chips that save data only while the device’s power is turned on. Non-volatile Memory chips such as NAND Flash save data even after the device is turned off. For example, DRAM helps to run programs on your device, whereas NAND stores your photos. Whereas DRAM is fast, NAND is slow to read and write data.

ASICs are simple, single-purpose chips used for performing repetitive processing routines such as scanning a barcode.

SoCs are essentially integrator chips. They are a relatively new type of chip that combines many chips and circuits in a single chip and may integrate things such as graphics, audio, camera, video and Wi-Fi.

Computing power

Chip improvements are behind the incredible increase in computing power and memory function that has allowed technology to advance to where it is today. 1956 to 2015, computing power increased one trillion-fold, thanks to chips. Think about this: the computer that navigated the Apollo missions to the moon was about twice as powerful as a Nintendo console. It had 32.768 bits of Random Access Memory (RAM) and 589.824 bits of Read Only Memory (ROM). A modern smartphone has around 100,000 times as much processing power, with about a million times more RAM and seven million times more ROM.

Chips enable applications such as virtual reality and on-device artificial intelligence (AI) as well as gains in data transfer such as 5G connectivity, and they’re also behind algorithms such as those used in deep learning.

All this computing produces a lot of data. By 2025, the world will be producing 175 zettabytes (ZB) of data per year, or roughly the equivalent of one billion terabytes (TB). For comparison, according to market intelligence company IDC’s ‘Data Age 2025’ whitepaper, if you were to store 175 zettabytes on DVDs, your stack of DVDs would be high enough to circle the earth 222 times.

The popularity of maturity

Chips are in demand – especially chips made using older, ‘dry’ lithography equipment. How is new innovation in this more mature sector helping to drive advances in society, and how is ASML helping chipmakers to stay on top of the demand for chips?

Does ASML make microchips?

No, ASML doesn’t make chips. ASML makes photolithography machines, which our customers use to mass produce chips.

What are microchips made of?

Microchips are printed on silicon wafers, which are made from silica sand.

What are microchips used for?

Microchips are used in almost every electronic device we use today, including smartphones, gaming consoles, cars and medical equipment.