KrF light source

Resolution

Projection optics

Wafers per hour

Key features & benefits

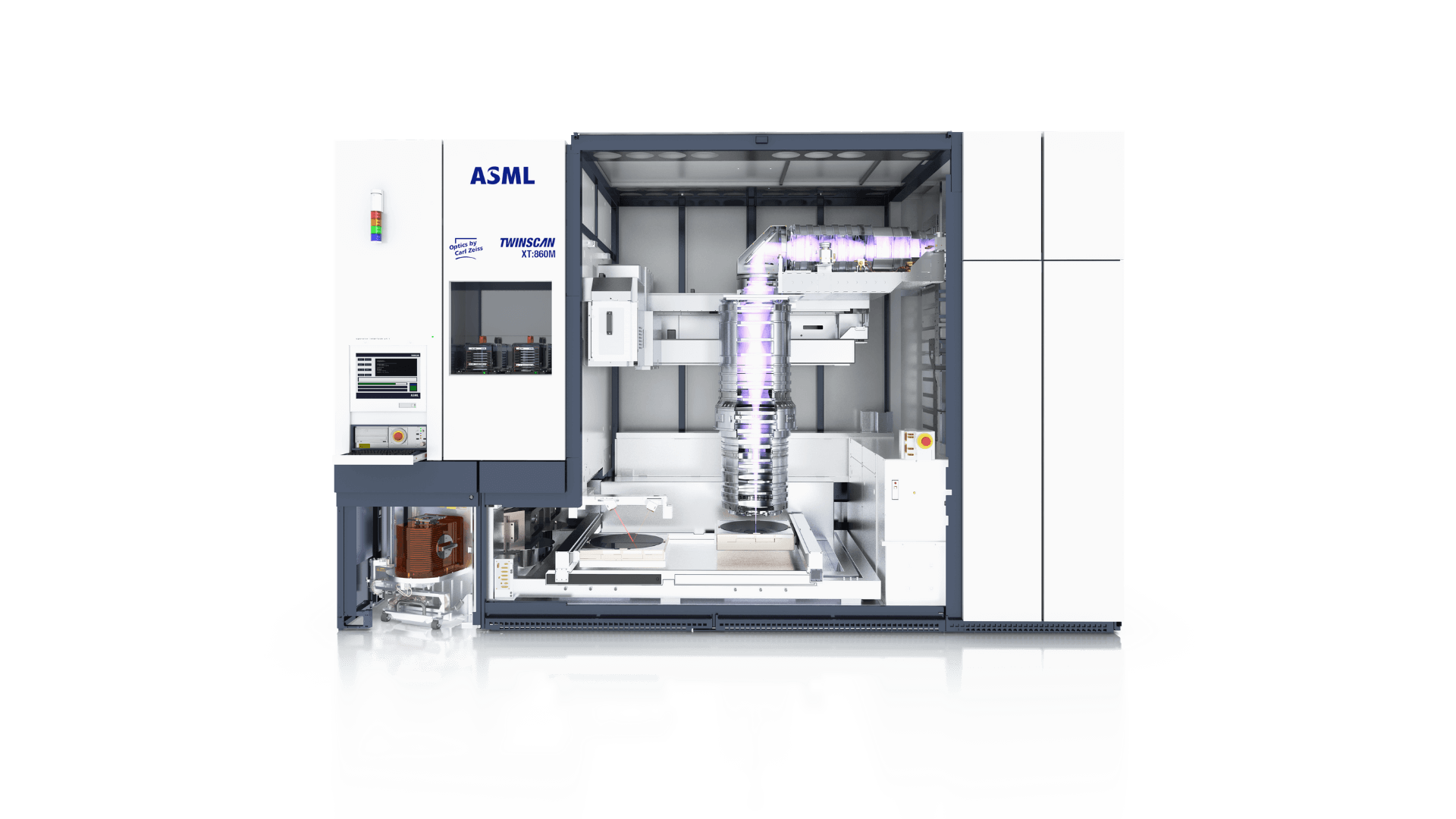

The TWINSCAN XT:1060K 248 nm step-and-scan system is a dual-stage lithography tool with the highest NA and productivity in the industry, designed for 300 mm wafer production. Extending critical KrF technology reduces our customers' cost per layer while allowing them to benefit from mature KrF processing.

The XT:1060K is ideal for metal, via and implant layers at the 2X nm technology node and beyond, both in Memory and Logic applications.

In addition, we provide imaging matching to other TWINSCAN KrF systems and excellent overlay matching to TWINSCAN ArF and KrF systems, which enables seamless integration in a high-volume manufacturing environment.

01. Productivity

Highly line-narrowed 40 W KrF lasers with variable frequency control, in combination with the high optical transmission of the optical system, provide a production throughput of ≥ 205 300 mm wafers per hour with the lowest possible cost of operation.

02. Optics

An in-line catadioptric lens design with advanced lens manipulators supports a full 26 x 33 mm field, 4X reduction and reticle compatibility with existing refractive designs. The AERIAL-E Illuminator enables continuous-variable conventional and off-axis illumination with an extended zoom maintaining high throughput.

03. Imaging performance

The XT:1060K is equipped with the latest overlay improvements, which allow customers to achieve a dedicated chuck overlay of ≤ 3.5 nm (full wafer) and a matched machine overlay of ≤ 5 nm (full wafer).

Its LithoGuide ILIAS allows for an extremely accurate system setup and sophisticated monitoring of imaging parameters.