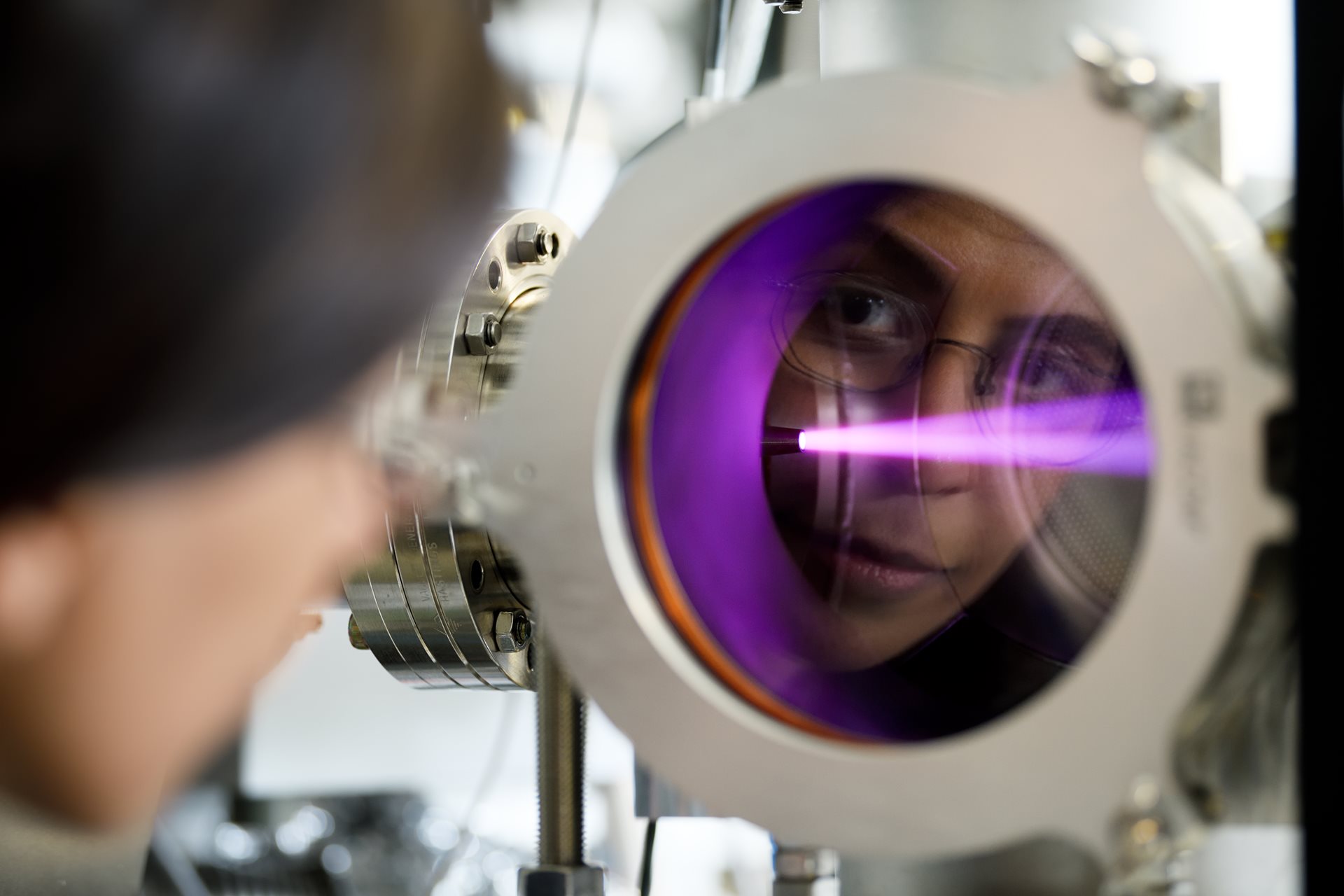

ArF light source

Resolution

Projection optics

Wafers per hour

Key features & benefits

The TWINSCAN NXT:2150i is the successor to the NXT:2100i. It offers a 15% improvement in on-product overlay – how accurately one chip layer can be printed on top of the previous one – as well as better imaging and a 5% increase in throughput.

Chipmakers will use the NXT:2150i for high-volume manufacturing of critical layers in advanced Memory and Logic chips as well as early development of future nodes. The system’s stability improvements will reduce costs for chipmakers because they can consistently get the same or better overlay with less user intervention.

A new diamond wafer table is key to the NXT:2150i’s improved overlay. It features a breakthrough material coating that ensures that the system maintains the best possible overlay performance without the need for regular wafer-table maintenance actions or metrology control updates. Additionally, the NXT:2150i’s on-product overlay performance is significantly less sensitive to lens and reticle heating effects thanks to several upgrades to the scanner’s real-time metrology control algorithms.

Upgrades to the wafer handler, reticle mask, reticle stage motors and power cabinets increase the system’s wafer-per-hour capability, which can reduce the cost per exposed wafer. System dynamics improvements ensure that the higher productivity can be achieved while still improving patterning performance.

The NXT:2150i also offers improved imaging thanks to a new laser with a higher repetition rate. Nonuniformity in the illumination can negatively impact the critical dimension uniformity by causing local variations in pattern edges. The new laser provides more uniform light intensity across the pattern, thereby reducing edge roughness and improving pattern quality.