ArF light source

Resolution

Projection optics

Wafers per hour

Key features & benefits

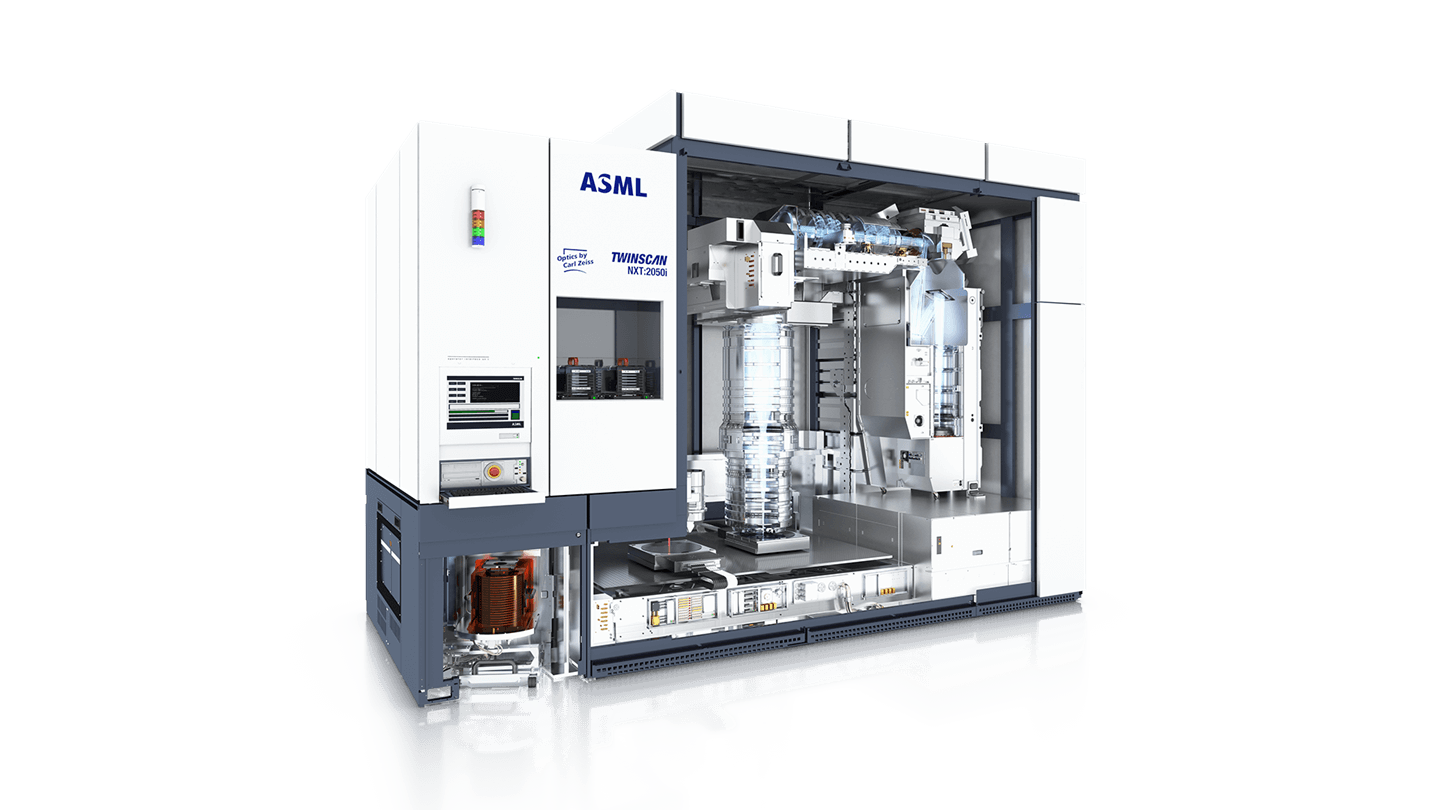

Built on the future-proof NXT4 platform, our TWINSCAN NXT:2050i pushes overlay limits and offers unparalleled productivity for an immersion lithography system.

The TWINSCAN NXT:2050i is where state-of-the-art immersion lithography system design meets advanced lens design with a numerical aperture (NA) of 1.35 – the highest in the semiconductor industry right now.

This step-and-scan system is a high-productivity, dual-stage tool designed for volume production.

By combining high productivity with unprecedented overlay performance, this system addresses multiple patterning requirements, providing a cost-effective solution for the manufacturing of 300 mm wafers at advanced Logic and DRAM nodes.

01. Productivity

The TWINSCAN NXT:2050i is raising the game for semiconductor productivity, able to produce 295 wafers per hour. This system is able to deliver 400 to 500 additional wafers per day, by reducing overhead times compared to earlier TWINSCAN systems. The redesigned wafer stage features a more powerful motor, able to accelerate faster and perform movements even more accurately.

The TWINSCAN NXT:2050i features a new immersion hood that reduces water loss, significantly improving defectivity performance. This translates to improved product yield and higher productivity through fewer slowdowns.

02. Optics

This system features a 1.35 NA 193 nm catadioptric projection lens that can achieve production resolutions down to 40 nm (C-quad) and 38 nm (dipole) and an in-line design supporting full 26 x 33 mm field size, 4X reduction and reticle compatibility with existing designs.

The lens elements of this system are equipped with manipulators to correct for optical aberrations, enabling maximum productivity for low-k1imaging. The lens fingerprint is now optimized in high-density and can be matched towards EUV.

The Parallel ILIAS (PARIS) sensor allows for a parallel measurement of optical aberrations throughout the projection slit, thus enabling a more accurate alignment, enhanced reticle heating correction and on-the-fly lens heating correction. The PARIS sensor used by the TWINSCAN NXT:2050i features an improvement in the sensor mount that translates to better positioning reproducibility.

03. Imaging performance

This system delivers improved cross-matching performance with our extreme ultraviolet (EUV) NXE systems. It can achieve a 2.5 nm cross-matching on product overlay. The reticle stage is equipped with enhanced clamps, improving not only the reliability of the system but also the overlay. The ORION alignment sensor, which offers increased accuracy of alignment measurements and enhanced process robustness, is future upgradable to 12 color mode.

The level sensor (UVLS-2) uses ultraviolet light to minimize the system’s sensitivity to process stack variations during in-line mapping of the wafer surface. The sensor has an increased measurement density which allows for greater leveling accuracy at the edge of the wafer.