2021 ANNUAL REPORT

Highlights

Explore our results and discover key information from our year in review

2021 ANNUAL REPORT

Introduction

2021, a year where strong partnerships enabled strong growth

2021 was a very challenging year, where ASML saw strong growth in a dynamic environment. We experienced higher demand for our systems than our production capacity could accommodate.

ASML reached €18.6 billion in net sales. This would not have been possible without our employees and partners. We’re now made up of more than 32,000 employees, and we expect this growth to continue. Our people are crucial to the success of our business.

Our industry has witnessed an unexpectedly strong increase in internet of things (IoT) applications, fueling the need for more distributed computing solutions. This global trend has made us take another look at potential future scenarios. We see an opportunity to achieve a step-up in our previously communicated revenue potential, which is now at €30 billion, based on a high-market scenario in 2025.

“The digital transformation and wider technology trends significantly shape our roadmap and are driving our industry forward.”

- Peter Wennink, ASML President and CEO

“With our customers, we share a commitment to increase the energy efficiency performance of microchips. Together, we have a vision to improve their energy efficiency three-fold every two years, over the next 20 years.”

- Martin van den Brink, ASML President and CTO

Our increasingly advanced lithography technology helps our customers to produce microchips – using fewer materials and consuming less energy during production – that are three times more energy-efficient every two years. We believe that the advantages of microchip scaling as expressed by Moore’s Law will continue throughout this decade and beyond.

We will therefore relentlessly invest in innovation. We will also make sure that ASML and its supply chain will be able to fulfill the increasing demand for more wafers with leading-edge and mature technology. We will do this by increasing the productivity of all our machine types and by adding more manufacturing capacity to our own.

As a global society we are faced with unparalleled challenges. But with its great workforce, partnerships and innovative power, ASML is looking toward the future with confidence, preparing for even more sustainable growth.

We can only grow by continuing to be a trusted partner for all our stakeholders – we would like to thank them for their commitment and support.

We are looking at a bright future, but we cannot do this alone.

Read more about this topic in the 2021 Annual Report (US GAAP)

2021 ANNUAL REPORT

Finance

Our performance in 2021

Net sales

Gross margin

Capital return

Earnings per (basic) share

All figures based on US GAAP

As a leader in the semiconductor industry, we have the right tools in place to execute our long-term financial strategy and expect to achieve continued sustainable growth for the years ahead.

2021 was another year of strong growth for our company, with significant net sales and margins. This was fueled by increases in sales and services across all markets. Our continued investments in technology leadership have created significant value for all our stakeholders.

Our net income increased to €5.9 billion in 2021 (up from €3.6 billion in 2020), resulting in an increase in the earnings per basic share to €14.36 in 2021 (€8.49 in 2020).

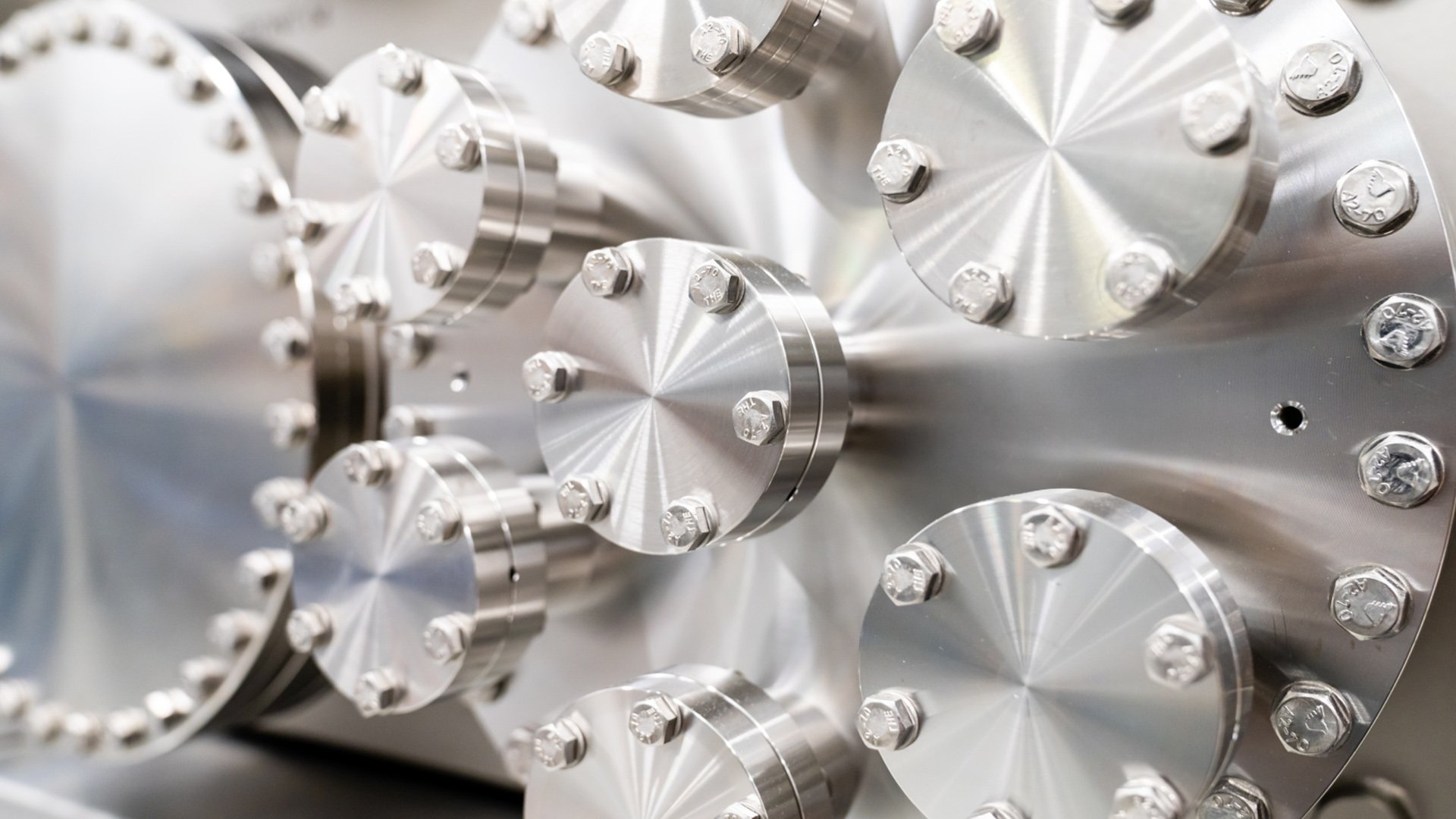

Customer confidence in EUV continued to grow. Since its introduction, our EUV installed base has produced more than 59 million wafers by the end of 2021, compared to 26 million wafers produced by the end of 2020. It is now used for more layers in advanced Logic chips and going through initial deployments in the Memory (DRAM) market.

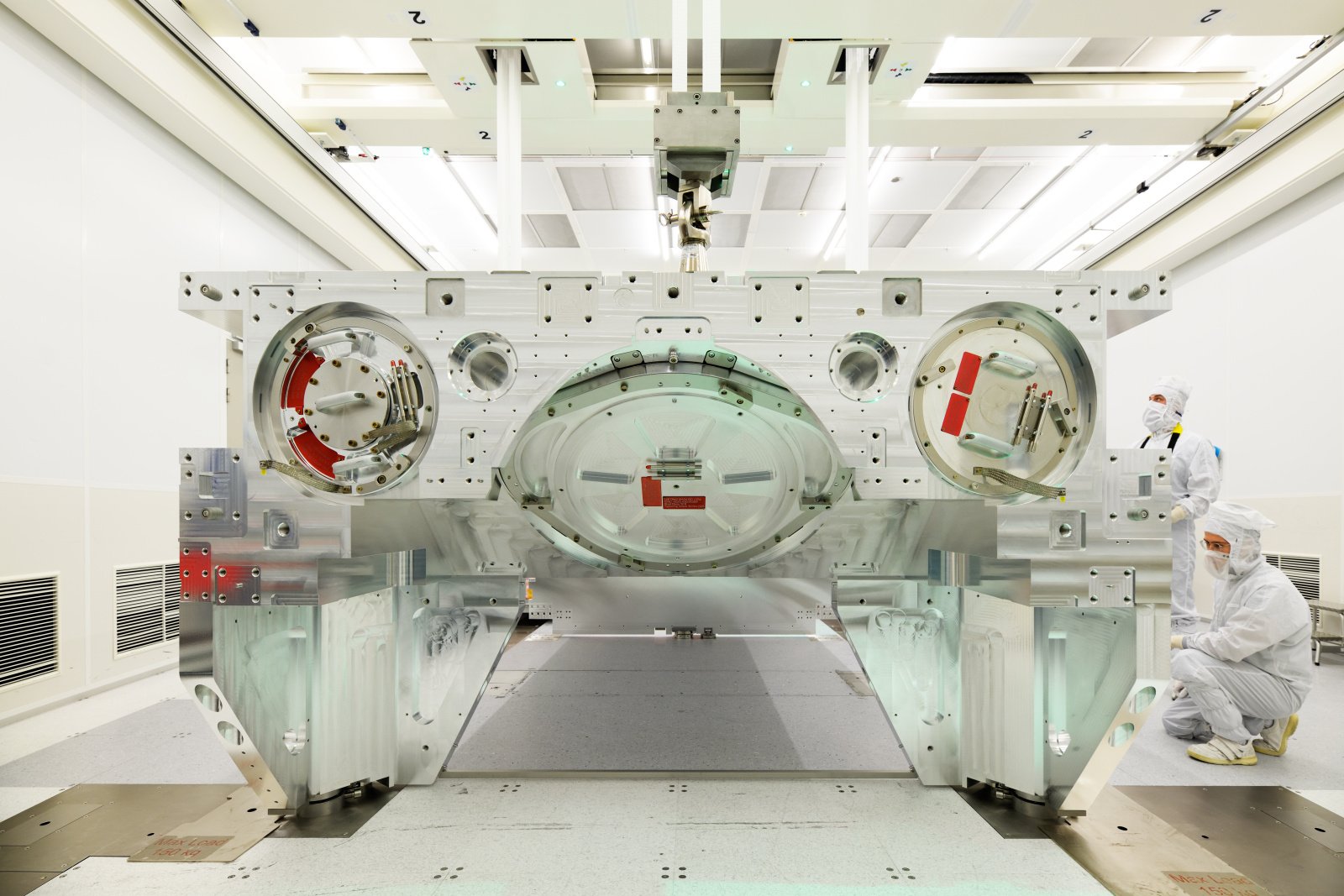

We continue to invest in the future of ASML, with a capital expenditure of €0.9 billion. This is in line with our roadmap to increase the value of EUV in high-volume manufacturing and the development of High-NA (EUV 0.55 NA). We are increasing our capacity to support the strong demand for DUV systems of all wavelengths and continue to innovate across our whole portfolio.

Total net sales and gross profit

In 2021, our net sales totaled €18.6 billion, an increase of €4.6 billion from 2020. Gross profit as a percentage of net sales increased to 52.7%.

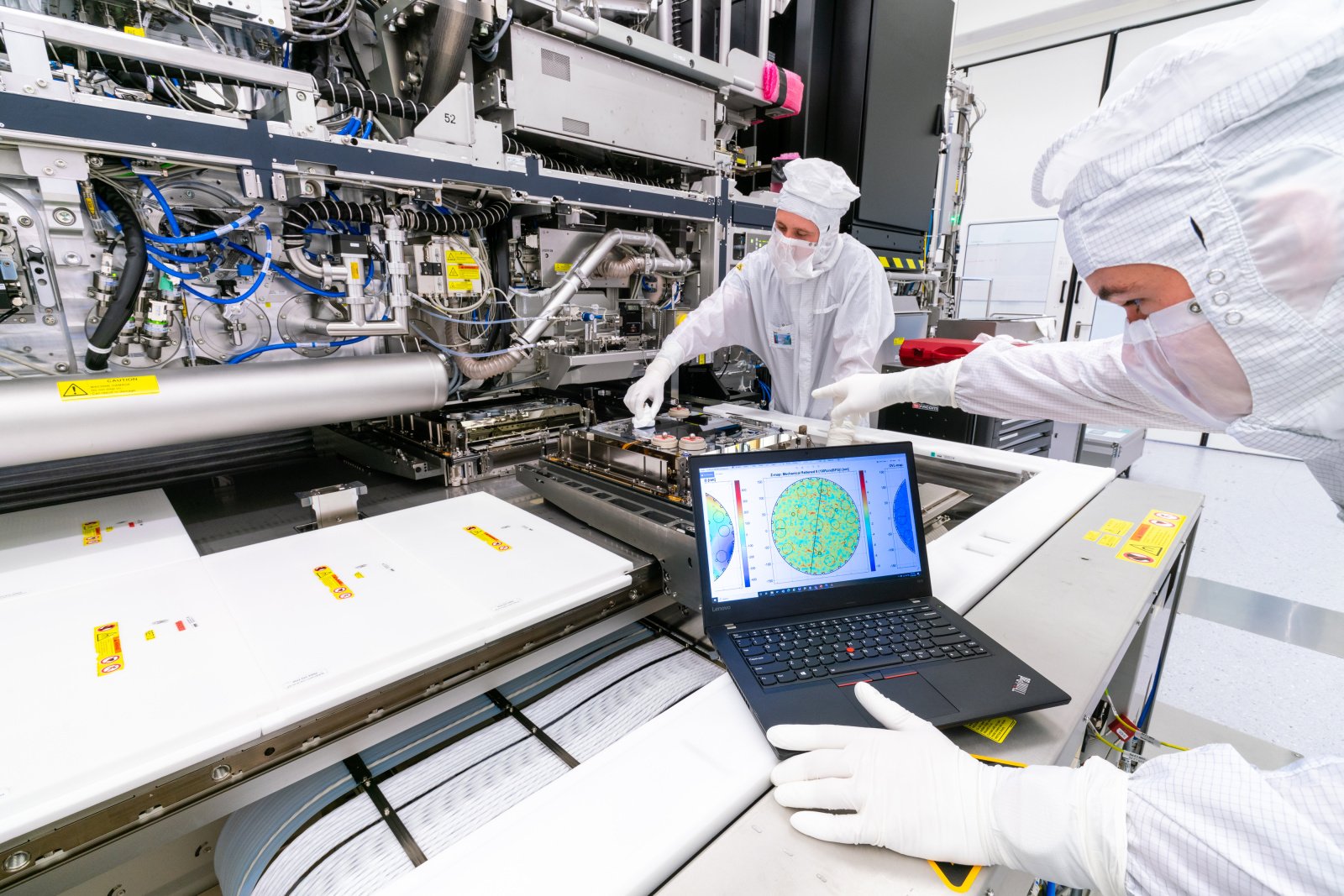

We met expectations in 2021 due to strong demand for all our systems in both Logic and Memory markets, especially for mature nodes. Profitability also increased, mainly due to the growth in sales of our most advanced DUV systems and the profitability of EUV systems (NXE:3600D). Strong growth in our installed base business was driven by productivity upgrades and the servicing of our growing EUV installed base.

System sales

Demand for systems is strong and sales increased in all categories, for all nodes. EUV system output increased to 42.

In 2021, we sold a total of 309 lithography systems (up from 258 in 2020). We saw a total revenue of €13.6 billion for all system sales, including metrology and inspection. New product introductions included the NXE:3600D, NXT:2050i, XT:860N, YieldStar 1385H and eScan 1100.

All system sales

Service and field option sales

Net service and field option sales amounted to €5.0 billion, an increase of 35% from 2020. This was driven by an increase in the sales of productivity and focus upgrade packages, in combination with a growing installed base.

With the global chip shortage, our customers have pulled forward demand for our productivity enhancement packages, which provide the most effective and efficient way to increase wafer output as they can be installed quickly.

Net service and field option sales

Investment in R&D

Our ability to innovate is crucial to our ongoing success. Our investment in R&D reflects our commitment to deliver on our technology and product roadmaps.

Our investment in R&D increased from €2.2 billion in 2020 to €2.5 billion in 2021. This is in line with our plans to enhance EUV high-volume manufacturing and invest in the development of High-NA (EUV 0.55 NA).

Our R&D focus for DUV is on productivity improvements for our installed base as well as next-generation systems for each wavelength. We continue to invest in our holistic software applications and metrology and inspection systems, including multibeam inspection.

R&D costs

Building for the future

We are investing in the expansion of our campus locations to future-proof our infrastructure and support strong customer demand.

In the United States, we opened a new campus in Silicon Valley. At our headquarters in Veldhoven, the Netherlands, our campus developments continued. We opened several new buildings including new office spaces, an auditorium and the 5L logistic center – increasing the capacity of this site by over 4,000 people.

Watch the video to see how our Veldhoven campus has expanded.

Returning capital to investors

Due to our strong financial performance, we raised our dividend and increased our share buyback scheme.

The total capital return value for 2021 was €10 billion. This was made up of €1.4 billion in dividends paid (comprising the final dividend of 2020 and the interim dividend of 2021) and €8.6 billion in share buybacks. Earnings per basic share grew to €14.36 from €8.49 in 2020.

We announced a new share buyback program of up to €9 billion to be executed by December 31, 2023 (replacing the €6 billion share buyback program from 2020–2022 which was almost completed).

Investor Day 2021

During our virtual Investor Day event, we took another look at our future potential scenarios, given the significant continued growth of our industry driven by the accelerated digital transformation.

Our leadership team shared how secular growth trends – as part of the digital transformation creating an increasingly connected world – as well as countries pushing for technological sovereignty, are fueling future demand across all market segments at both advanced and mature nodes.

Read more about this topic in the 2021 Annual Report (US GAAP)

2021 ANNUAL REPORT

Environment

Aiming to reduce our environmental footprint wherever we can

We are committed to lowering our carbon footprint and managing the waste from our operations and the use of our products and services. Working with partners in our value chain, we have increased our environmental ambitions in 2021.

Climate and energy

Maximizing green energy consumption and lowering our carbon footprint.

Energy consumption

Renewable electricity

Net emissions footprint

(scope 1 & 2)

Value chain emission intensity per €m revenue

(scope 3)

Climate change is a global challenge that requires urgent action by everyone, including us. At ASML, we are committed to reducing our carbon footprint. In terms of our carbon footprint, we identify three impact areas: the direct emissions from fossil fuels (scope 1) used on our premises, the indirect emission from the electricity consumption (scope 2) on our premises, and the indirect emissions in our value chain (scope 3) from upstream supply chain and downstream use of our products by customers.

Reducing our carbon footprint

We take direct responsibility over the CO2 emissions from our own operations (scope 1 and 2) and aim to achieve net zero CO2 emissions by 2025.

Our scope 1 and 2 carbon footprint strategy is built on three principles: reducing energy consumption wherever we can, using only green renewable energy unless no other solution is possible or reasonably feasible, and compensating for residual emissions.

To achieve our scope 1 goal of carbon neutrality by 2025, we aim to have a direct energy saving of 100 TJ (or 2.5 kt) by executing the more than 25 projects we have defined in our energy master plan.

With regard to scope 2, our ambition is to increase the share of direct green energy purchases from renewable electricity sources close to our premises in the Netherlands, and to reduce the share of certificates.

In 2021 we expanded our environmental reporting scope from 20 locations – which covered around 90% of our worldwide CO2 emissions – to 57 locations which encompass more than 95%. Taking all these locations into account, the share of renewable electricity we used globally was 92% in 2021. In the Netherlands and the US, we achieved our goal of using 100% renewable electricity. The renewable market situation in Asia is complex and we continue to investigate options to meet our ambitions in this region as well.

We recognize that our environmental impact goes beyond our operations. Most of the environmental impact of energy consumption in our value chain (scope 3) comes from the greenhouse gas emissions of our suppliers and the use of our products by our customers.

Our scope 3 target for 2025 is to reduce the intensity level compared to our 2019 baseline of 0.55. Intensity is measured by the total scope 3 emissions (in kt) normalized to the total revenues (in € million). Our supplier sustainability program is a key enabler in reducing our upstream footprint. And by executing our product energy roadmap, we aim to push the energy consumption of our EUV systems down and drive energy efficiency per wafer up.

Energy efficiency

While increasing the energy efficiency of our manufacturing processes and buildings, our main focus is on driving down the energy use of our products.

With each new generation, microchips are becoming more energy efficient, which facilitates more computations or data processing for the same unit of energy. But more advanced and complex chips require more complex lithography systems with higher energy consumption. Our ongoing challenge is to reduce the energy use of our products while also meeting our customers’ expectations for higher performance.

Our product efficiency strategy focuses on making our lithography systems more efficient. EUV systems, our most advanced and therefore the ones that require the most energy, are our priority. By 2025, we aim to reduce the energy use per exposed wafer pass of our future-generation NXE (0.33 NA) systems by 60%, as compared to the NXE:3400B (baseline 2018).

Circular economy

We are committed to a circular economy and to ensure that any materials we use retain and generate as much value as possible for us and for our partners in the ecosystem.

Waste generated per €m revenue

Material recycling rate

PAS 5500 systems still in use

(from total ever sold)

Value of parts re-used

The cornerstone of our circular approach is the modular design of our products. It enables us to upgrade a system to a higher performance level at a customer site rather than having to replace the entire product. Nearly 94% of the lithography systems we’ve ever sold are still in use at customer sites – this highlights our ability to contribute to a circular economy.

To minimize waste and maximize resources, we focus on three core strategies:

-

Reduce waste in our operations

-

Re-use parts and materials from the installed base

-

Recycle mature products through refurbishment

Reduce waste in operations

We focus on recycling and not creating waste.

In 2021, we generated 5,878 tonnes of waste from operational and construction activities on our sites. Nearly 77% of this was recycled (from 85% in 2020). Compared to 2020, the total amount of waste increased by nearly 12% (from 5,257 tonnes), mainly due to both the increase of our reporting scope from 20 locations in 2020 to 57 locations in 2021 and the growth of the company. Waste reduction programs for the expanded scope need to be defined and implemented, aiming at 2022.

We have set ourselves two targets to reduce our waste footprint. The first target is to reduce our waste intensity – the amount of waste generated in kg per € million revenue – by 50% in 2025 compared to 2019. The second target is to increase our material recycling to 85% by 2025. We prioritize solutions to reduce, re-use and recycle our waste as much as possible, rather than sending it to an incineration plant or landfill.

Re-use parts

In 2021, we accelerated our efforts on re-use and extended our re-use policy to apply to all product-related packaging, parts, materials and tools.

We aim to increase our rate of re-use to 95% of our parts by 2025. In 2021, our re-use rate was 85%.

We accelerated our efforts on re-use, formalizing and adding structure to many parts of this process. Our dedicated cross-sector Re-use department aims to drive this change on a global scale. Building a re-use mindset across the company is critical to achieving our targets. We have a network of Re-use representatives promoting good practice and a new Re-use Board to monitor progress.

We further embedded our re-use commitment by enhancing our Supplier Sustainability Program. Suppliers are now asked to commit to increasing circularity through re-use. We also aim to increase the use of qualified ‘As-New’ modules in our systems. We now have over 75 ‘As-New’ release projects ongoing at over 25 suppliers.

We encourage employees to think of used parts as having ‘potential’ rather than being seen as ‘waste’.

We are extending local repair centers for service parts and materials and setting up global repair centers for factory materials. There are currently local repair centers in South Korea, Taiwan and China, with plans for all our major customer regions to eventually have one or more in place. Global repair centers will also be set up at each of our factory hubs in Wilton and San Diego (US), Linkou (Taiwan) and Veldhoven (the Netherlands).

Recycle products through refurbishment

We refurbish, upgrade and offer associated services for our older lithography systems to extend their lifetime.

Thirty years after the introduction of our PAS 5500 platform, 90% of those ever built are still in use, with around 1,800 systems operational at customer sites worldwide. Up to 2021, we have refurbished and resold well over 500 systems and we will continue to do so.

We also refurbish the first generation of TWINSCAN AT and XT systems and have added NXT:1950-1980 systems to the portfolio. In 2021, we celebrated the 100th refurbished TWINSCAN, which also marked the 20th anniversary of our TWINSCAN refurbishment program.

Read more about this topic in the 2021 Annual Report (US GAAP)

2021 ANNUAL REPORT

Social

When our ecosystem thrives, we thrive

We aim to have a positive role in society – for our employees, the communities around us and everyone involved in our innovation ecosystem.

Our people

Our employees are critical to the performance of our organization and our long-term success as a company.

Total employees (in FTE)

Nationalities

Attrition rate

Employee engagement score

Our business strategy and the growth of our company bring challenges as well as opportunities. Increasing demand is being placed on the semiconductor industry, while our organization needs to adapt to support growth.

The needs of our growing workforce are changing. To stay successful in the future, we have translated our strengths to our current reality and defined our People Vision: We empower each other to thrive, fueling our growth, happiness and business success. ASML’s people vision sets out our ambition for the future, supporting our values and what we stand for. Everyone throughout the organization has an important role in this vision.

Our strong growth means we need to attract and onboard large numbers of employees. In 2021, we hired 4,373 new payroll employees (FTE), welcoming our 30,000th employee in July. Our workforce grew to a total of 32,016 at year-end.

Highly skilled people with a technical background are scarce in the labor market, and competition is growing. Our overall attrition rate (the percentage of employees leaving our company) was on target and below the industry average in every country we operate in. However, it did rise from 3.8% in 2020 to 5.4% in 2021. We attribute this increase to the effects of the pandemic, the global shortage of employees across many industries, and the booming semiconductor industry that is providing plenty of job opportunities.

Employee experience

We aim to provide the best possible employee experience, so that the talent we need chooses to work for us and wants to stay for the long run.

We want to offer our people the best possible employee experience at all our sites. Employee experience is the sum of all experiences an employee gains through the interactions with the company at each stage of the employee life cycle, from attracting and onboarding talent to attrition. That’s why we focus on employer branding and employee engagement.

Employee engagement depends on a wide variety of factors and activities, geared to help our employees to develop their talent, feel respected and work to the best of their abilities, such as onboarding experience, learning and development, diversity and inclusion, and leadership.

We measure employee engagement through our annual we@ASML survey. In 2021, we received a score of 78% (80% in 2020) – 2 percentage points above our external global benchmark of 76% – plus valuable feedback for improvements.

Employer branding

With the demand for top-tier talent increasing year-on-year, strong employer branding is vital to ensure ASML continues to attract the talent we need.

We have defined employer brand targets for the different local labor markets by 2025. We currently measure how ASML is perceived by external audiences – and potential employees in particular – by monitoring our position in an independent external employer-branding ranking.

We are a culturally diverse organization, with employees of 122 different nationalities. But we recognize that our diversity and inclusion journey includes many more opportunities for success, as well as challenges to solve.

Our ambition is to promote more diversity in our workforce. We believe the most effective way to address this is by focusing on developing our existing team members and increasing the diversity of our talent pool. Creating an environment where all feel welcome, know they belong and see a career path in front of them requires diversity at all levels of the organization. We aim to increase the diversity of our workforce by fostering a culture that is inclusive of all employees. We have set an inclusiveness goal to be on par with the top 25% performing companies in 2024.

We’ve set goals to achieve a women hiring rate of 23% by 2024 – currently we are standing at 20%. In addition, we aim to increase the representation of female leadership from 8% in 2021 to 12% by 2024.

Community engagement

As a global technology leader and employer, we play an active role in the communities we operate in.

ASML Foundation

Education

Arts & culture

Local outreach

Value of donations

Education

In 2021, ASML supported 64 education projects across the regions where we operate (the Netherlands, US and Asia). The total value of these projects amounted to €4.3 million.

Find out more about our education program

Arts and culture

In 2021, we supported 14 arts and culture projects across the Netherlands, Asia and the US. The total value of these projects amounted to €1.5 million.

Find out more about our arts and culture program

Local outreach

In 2021, we supported 55 local outreach projects across the regions we operate (the Netherlands, US and Asia). The total value of these projects amounted to €2.3 million.

Enabling a more inclusive and equitable society for all through education.

The ASML Foundation operates independently from the company and is our charity of choice. In 2021, the Foundation donated around €2 million (€1 million in 2020) to support 22 initiatives in eight countries, aiming to reach 775,000 young people. It mainly supports projects and programs in Europe, the US and Asia that address specific needs in those regions.

Innovation ecosystem

We innovate in a collaborative ecosystem to ensure the fast pace of innovation in our value chain. In 2021, we worked with 121 different R&D partners.

R&D partner agencies

Support to high-tech startups and scaleups

Contribution to EU research projects

Around the world, our teams co-develop within a wide network of technology partners, such as universities and research institutions. We also cooperate with private partners in research and innovation projects subsidized by the European Union and its member states. In 2021, we contributed €30.3 million to EU research projects.

We support innovative startups and scaleups to help strengthen the high-tech ecosystems in the Brainport Eindhoven region (in the Netherlands) and other regions where we operate by mentoring and sharing our expertise. In 2021, we provided nearly €1 million of in-kind support to high-tech startups and scaleups. The amount consists of 2,100 hours of support and €0.4 million in cash.

Our supply chain

We focus on long-term relationships and close cooperation with our supplier network to achieve the innovations we strive for.

Total sourcing spend

Total number of suppliers

Completion of RBA assessment by key suppliers

Suppliers with overall ‘high-risk’ score on sustainability (RBA) and ASML assessment

ASML relies on an extensive supply base of nearly 800 product-related (PR) suppliers and around 3,900 non-product-related (NPR) suppliers. We are committed to being a responsible business partner. Our goal is a sustainable and resilient supply chain. To achieve this, we continuously seek to enhance our Supplier Sustainability Program.

In 2021, we increased our focus on the environmental footprint of our supply chain and extended the program to include the following: responsible minerals sourcing, reducing carbon footprint, increasing our re-use capabilities and reducing waste, improving information security, and ensuring business continuity.

Read more about this topic in the 2021 Annual Report (US GAAP)

2021 ANNUAL REPORT

Governance

Ensuring ASML is managed in the best interests of its stakeholders

Supervisory Board female members

Internal pay ratio (CEO versus average per FTE)

Speak-up reports

We champion integrated corporate governance and seek to build a relationship of respect, mutual benefit and trust with our stakeholders.

We build trust between ASML and our stakeholders – shareholders, customers, suppliers, employees and society – through accountability and transparency. We are guided by our values of challenge, collaborate and care. Our values are part of a shared belief system within ASML that influences how we make decisions, taking into account the interests of all our stakeholders. These values also guide us in our interactions with colleagues, customers, suppliers, shareholders and society as a whole.

Continuous stakeholder engagement, in which we embrace open dialogue and knowledge-sharing through various channels and at a variety of levels, is important in our innovation-driven industry and helps us to identify areas of improvement.

We are a well-governed company and have structures in place that enable us to stay on track to deliver on our targets and report on our performance.

Supervisory Board

The Supervisory Board focuses on long-term and sustainable value creation. Their goal is to ensure that the Board of Management pursues a strategy that secures ASML’s leading position as a supplier of holistic lithography solutions to the semiconductor industry.

In 2021, their agenda centered on the execution of the strategy, financial and operational performance, business developments, and people and organization.

The Supervisory Board attaches great importance to its composition, independence and diversity and strives to meet all the associated guidelines and requirements. The Supervisory Board currently consists of eight members.

Find out more about the Supervisory Board

Responsible business

As a global leader in the semiconductor industry, we have a responsibility to lead by example.

Our purpose is clear, and we want to reflect our values in everything we do in pursuit of this purpose. Anywhere we operate, we believe that conducting our business with honesty and the highest standards of integrity is essential to value creation for our stakeholder groups and the long-term success of our company.

In 2021, our effective tax rate increased to 15.2% of income compared to 13.7% in 2020 (based on US GAAP). To be more transparent in how we manage taxes and contribute to society, as of this year we decided to enhance communication on our Approach to Tax.

We updated our Speak Up & Non-Retaliation Policy to encourage people to express their concerns with the company without the fear of retaliation.

We started the Security Circles of Trust initiative to create cybersecurity awareness among our innovation ecosystem partners in the Brainport Eindhoven region in the Netherlands.

Find out more about governance at ASML

Read more about this topic in the 2021 Annual Report (US GAAP)