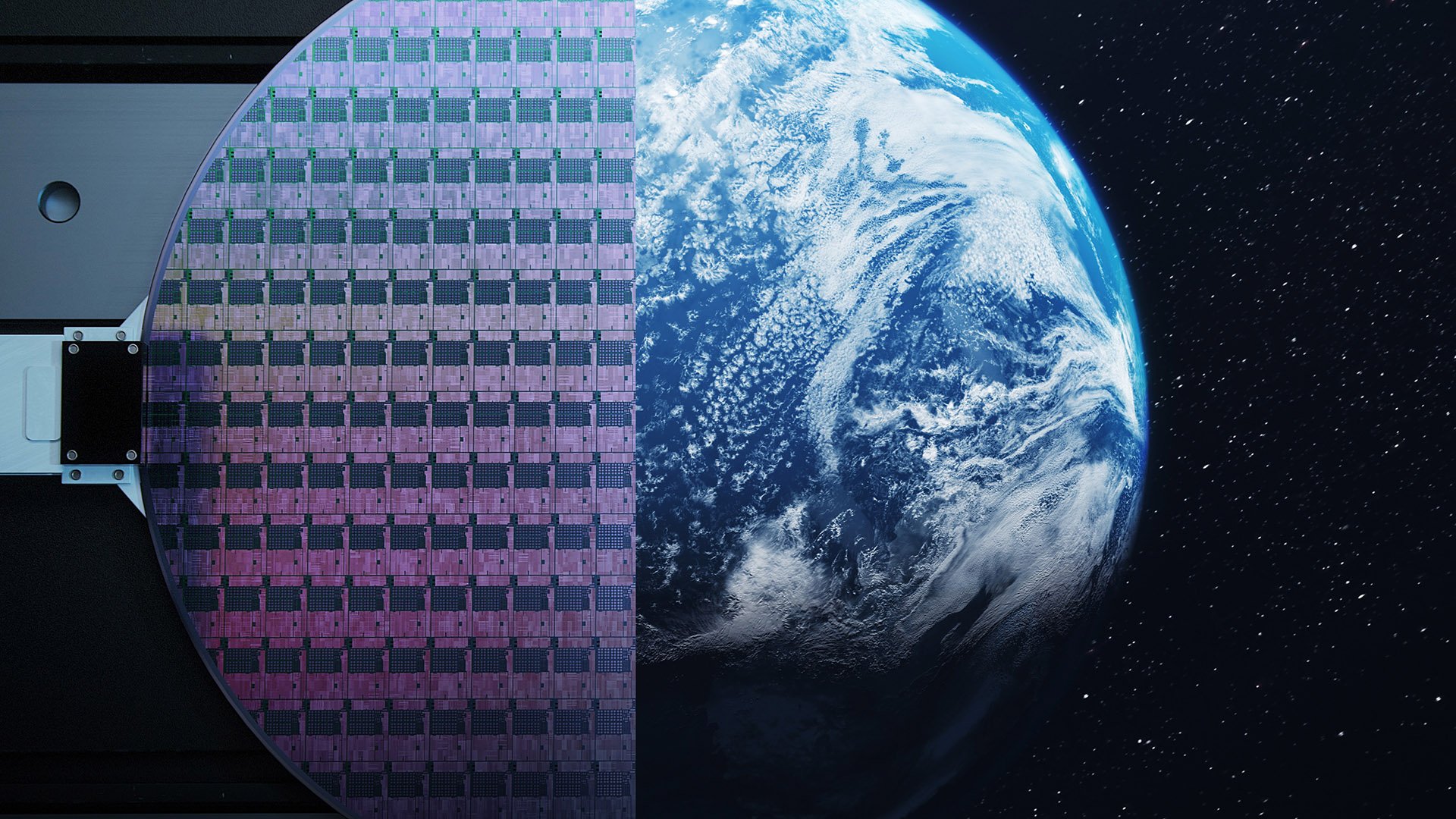

Our world-class supplier network helps us to achieve the innovations we strive for.

At ASML, we rely heavily on our supplier network to achieve the innovations we strive for. Our suppliers are critical to our value chain and our ambition to be a sustainable leader in the semiconductor industry. We need a responsible value chain to deliver the systems and new technologies that can provide answers to the challenges faced by society.

With over 5,000 suppliers in our total supplier base, we invest in developing our supply landscape to help suppliers meet our requirements with regard to quality, logistics, technology, cost and sustainability.

Working with our suppliers

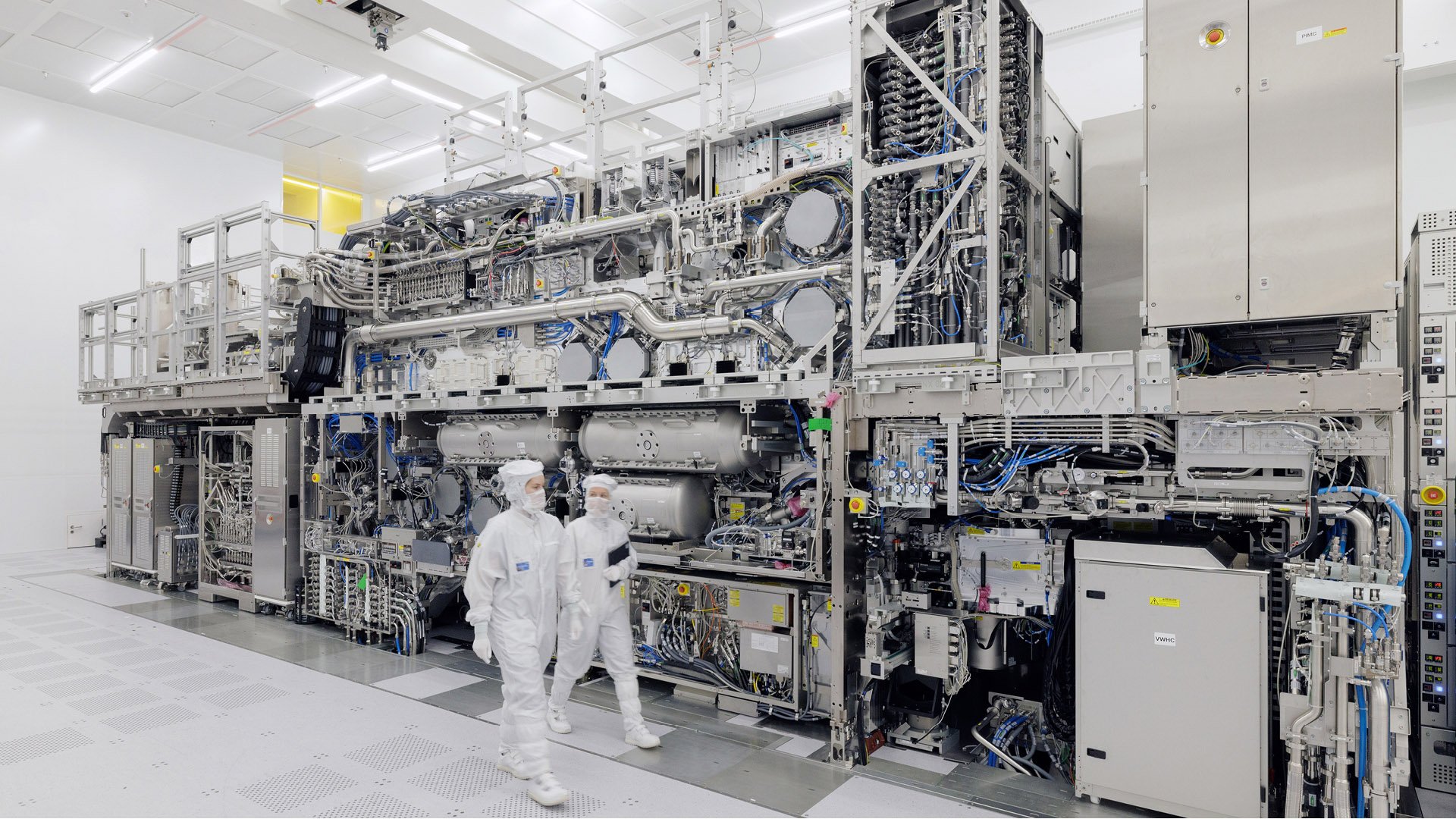

Building strong, strategic, ‘win- win’ relationships with our partners, while navigating short-term challenges, is essential to our future success. We operate in a niche market characterized by the production of high-value products in relatively small quantities and involving thousands of specialized parts.

We collaborate with our suppliers to develop, manufacture and deliver the innovative and unique parts used in our lithography systems. We build long-term and mutual beneficial partnerships with strategic, critical suppliers, like our partnership with Carl Zeiss SMT.

We place high importance on supplier performance management, value chain risk management and playing a full part in a responsible value chain. To ensure a robust value chain, we require our suppliers to meet our high standards regarding the quality, logistics, technology, cost, and sustainability of their products and services and conduct annual risk assessments for our critical suppliers, evaluating various risk areas.

Sustainability of our suppliers

We are committed to conducting our business in a caring and accountable manner, and being recognized as a responsible business partner. Since 2011, we have been a member of the Responsible Business Alliance, the world’s largest industry coalition dedicated to corporate social responsibility in global electronics supply chains.

We have adopted the RBA Code of Conduct, which sets out ethical and environmental standards. We expect our suppliers and their suppliers to acknowledge and comply with its requirements. With over 5,000 suppliers, we apply a risk-based approach to determine which suppliers are in scope for our more detailed due diligence process.

Read more

Conflict minerals

Like many companies in the electronics industry, ASML and our suppliers use minerals essential to the manufacturing process. The four main minerals concerned are tin, tantalum, tungsten and gold, also known as 3TG.

We are committed to responsible sourcing of materials in our supply chain. We support international efforts to ensure the mining of 3TG minerals from high-risk locations does not contribute to conditions of armed conflict or human rights abuses in the Democratic Republic of the Congo or any neighboring countries.

We also encourage our suppliers and sub-suppliers to have policies and due diligence measures in place to ensure the 3TG minerals we use are responsibly sourced.

Building relationships through Annual Suppliers’ Day

Our annual Suppliers’ Day helps us foster strong relationships with suppliers. The day allows suppliers to familiarize themselves with our strategy and targets, including through presentations from senior leadership. It is also an opportunity for us to present awards to suppliers for their contributions to ASML.

2024 Annual Report

For more information, download our 2024 Annual Report for full details of targets and performance data.

Sustainability

Our key themes