By 2030, we aim to send zero waste from our operations to landfill and incineration.

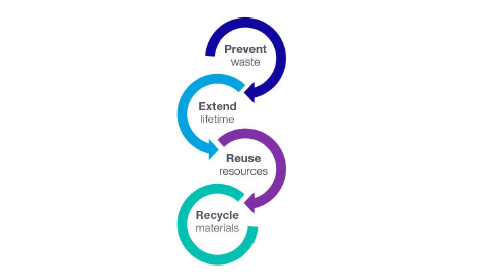

We aim to maximize the value of our systems, reusing resources as much as possible, while minimizing waste, decoupling our growth from resource consumption, and recycling materials.

Through our circular economy approach, we aim to ensure our products and services retain and create as much value as possible for us and our partners in the ecosystem.

Our approach to achieve this is designing products for longevity and reuse, creating closed-loop supply chains and encouraging the recycling of materials. Our strategy includes the following principles:

- Prevent waste from our assets, systems and processes by redesigning them, in collaboration with our suppliers and customers, to limit their environmental impact

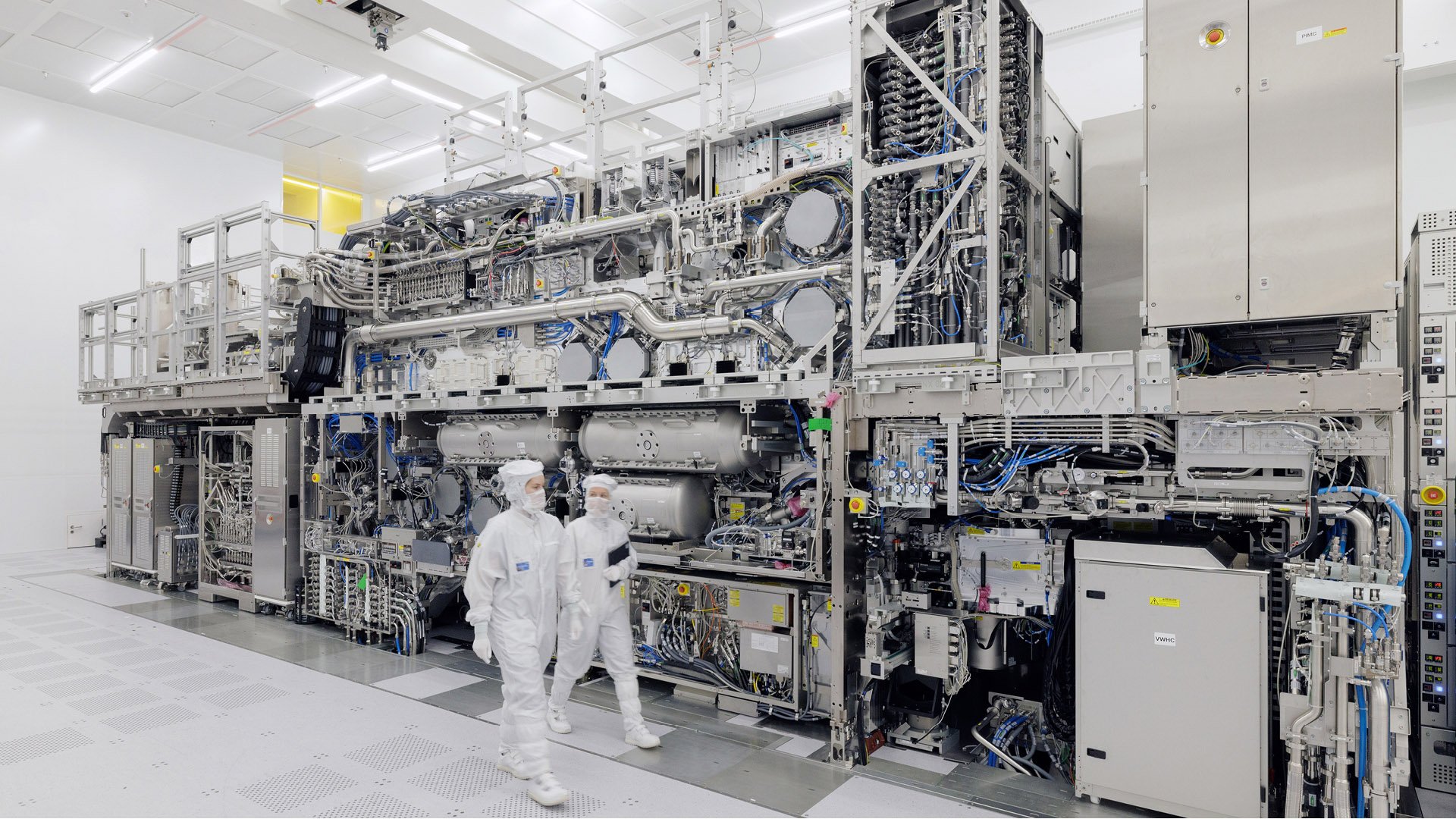

- Extend the lifetime and productivity of our systems and assets to maximize their usage throughout their life cycles

- Reuse resources, parts, tools, packaging and goods across the value chain

- Recycle materials if we can no longer apply any of the previous principles, avoiding incineration and landfill

Prevent waste

We are rethinking and redesigning systems and processes to avoid waste, focusing on design, sourcing and quality.

We design our systems to last for as long as possible, using feedback loops to learn from failure modes and repair activities to continuously improve. We work with suppliers to increase our use of recycled materials which can be upgraded, refurbished, repaired and recycled. A dedicated team enables us to take a sustainable packaging approach while also ensuring the safe transport of our systems.

Extend lifetime

A well-maintained ASML system can last for decades and create value for more than one customer. We aim to keep systems in use as long as economically and environmentally possible, focusing on service, upgrades and refurbishment of assets, systems and goods.

Our refurbishment strategy focuses on buying back systems that are not operational in the field, harvesting parts from decommissioned systems and managing the continued availability of spare parts.

We‘re committed to reusing parts, packaging and tools across the value chain, focusing on return, recondition and repurposing processes.

We optimize return flows by collaborating with customers and suppliers, while learning from system usage and product returns. We recondition parts and packaging through global and local repair centers, suppliers and partners, at the best location with the lowest environmental impact.

Recycling our waste plays a key role in closing the material loop. We aim to recycle materials instead of incinerating or disposing of them to landfill.

We’re focusing on collection, analysis and reporting processes to identify drivers of waste and gain insights into reasons for disposal, providing feedback to prevent waste and improve opportunities for recycling.

We aim to maximize waste separation at our sites to enable increased recycling rates and easy recycling for waste haulers.

2024 Annual Report

For more information, download our 2024 Annual Report for full details of targets and performance data.

Sustainability

Our key themes