INTRODUCTION

Business as (un)usual

How COVID-19 shaped 2020

In every part of the world, the entire year was dominated by a pandemic that changed the way we live, work and interact with each other.

Businesses and entire industries had to adapt to the new situation overnight, and many struggled to stay afloat. In 2020, ASML had to navigate these challenging circumstances, alongside thousands of other businesses.

Two priorities

We have two very clear priorities in our crisis response and communications. Our number one priority is to ensure the health and safety of our people and their families. The second priority is to ensure business continuity: manufacture our products, provide service to our customers, and develop future products according to our roadmap.

In all our health and safety measures, we follow the guidelines of the World Health Organization and local health authorities. And although we developed an ASML-specific policy worldwide, we follow national government measures in the regions where we operate.

We also learned how important our company values are and why we need them now more than ever.

When the future is uncertain and there are no easy answers, these values of ‘challenge, collaborate and care’ provide the foundation for everything we do. In 2020, we lived our values, and they united us in many ways. One of ASML’s strengths as a company has always been that its people pull together when we need to most. The past year certainly stands as testimony to this strength.

Our performance

We know that COVID-19 is not behind us – but looking back on 2020, we can say we have delivered on our priorities. With a focused approach, the dedication of our employees, and the support of all of our partners, suppliers and customers, we surpassed our expectations and delivered another record year.

Continue scrolling to find out more about how we

responded to the pandemic, our results and achievements.

Technology

Forging ahead by working together

2020 was a year of breakthroughs, innovations and rewarding collaborations

Wafers produced by EUV installed base

(accumulated)

R&D expenses

Based on US GAAP

Hours support to high-tech startups and scaleups

Contribution to four EU subsidy projects

We innovate and develop technology with the help of our partners and collaborative knowledge network.

We have built a strong innovation ecosystem and co-develop expertise within our wide network of R&D partners.

We work closely with our customers to understand how our technology best fits their needs and challenges. We share knowledge and risks and align our investments in innovation.

Our wider network includes technology partners ranging from universities to research institutions. In 2020, many of these partnerships delivered notable results.

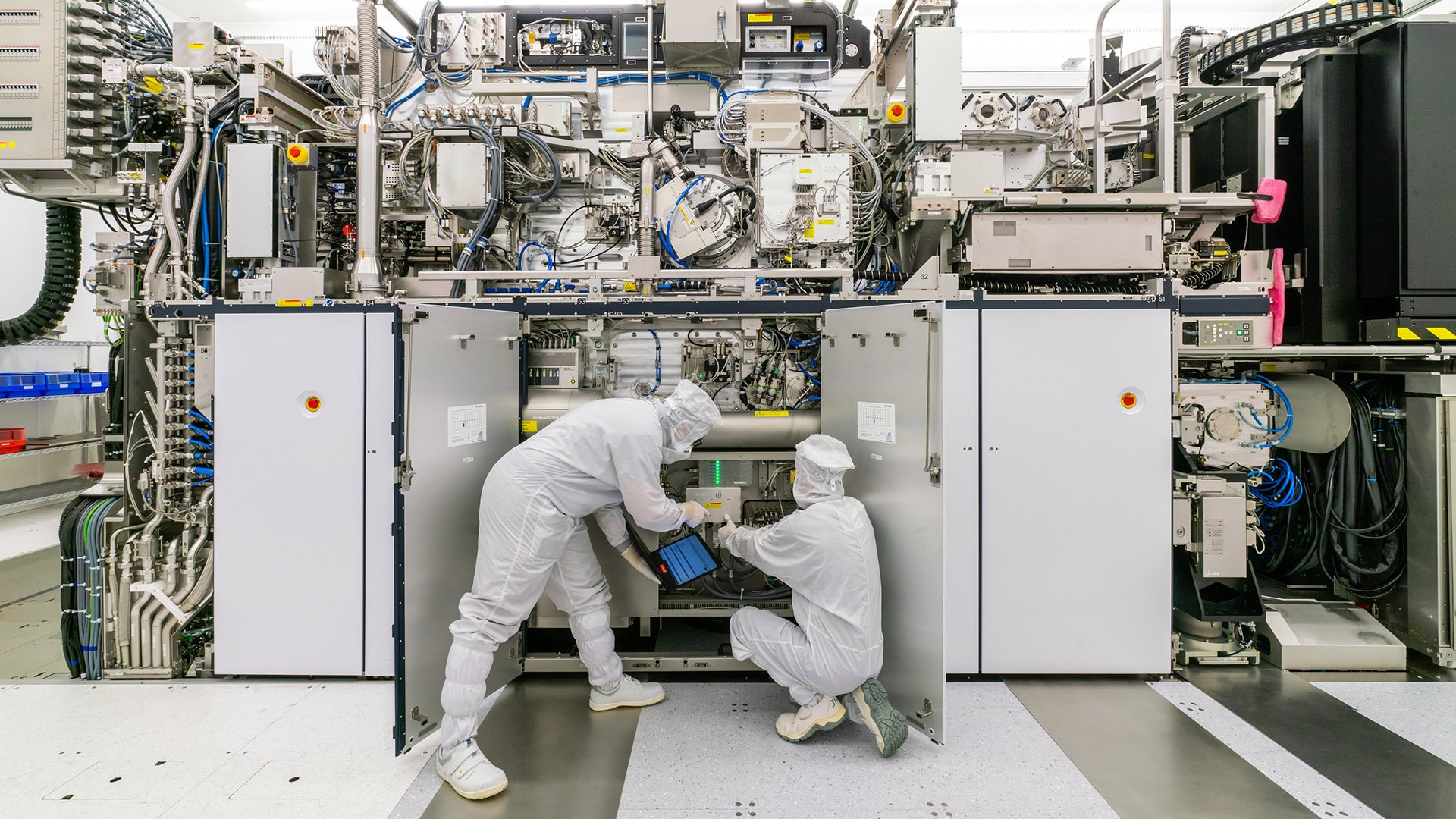

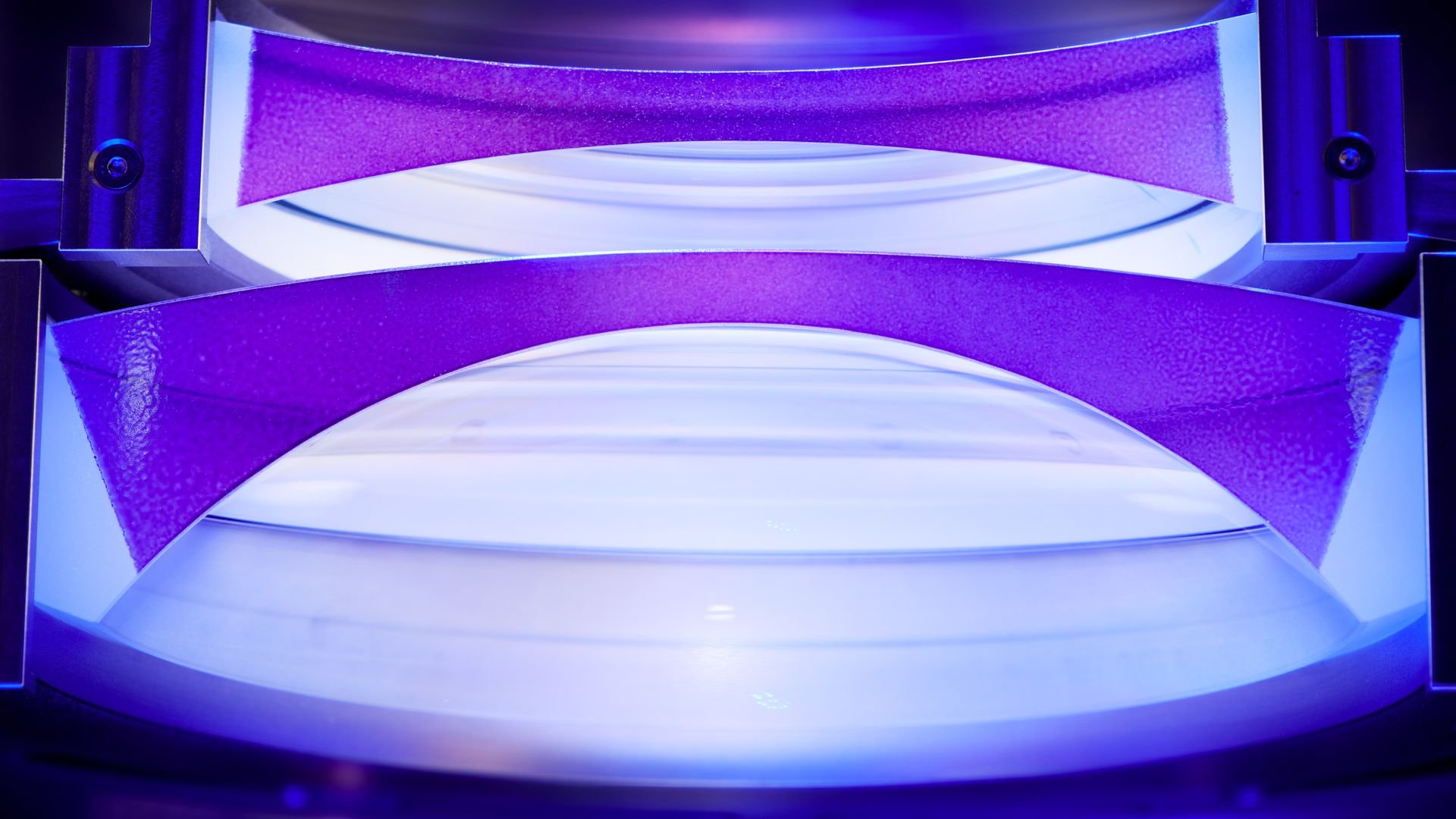

For example,imec in Belgium made a breakthrough, demonstrating how our NXE:3400B EUV system could print narrow pitch lines (24 nm) in a single exposure. This will help imec and partners to develop resist materials that will support the introduction of High-NA, our next-generation EUV system.

We collaborated with

Lam Research in the US to introduce a new dry photoresist technology for EUV patterning, offering a significant improvement in resolution, productivity and yield. Fundamental research at the Advanced Research Center for Nanolithography (ARCNL) in the Netherlands improved our understanding of the way atoms react when we generate EUV light. The resulting discovery that many more electrons than expected can contribute to EUV light will help us to further optimize EUV sources in the future.

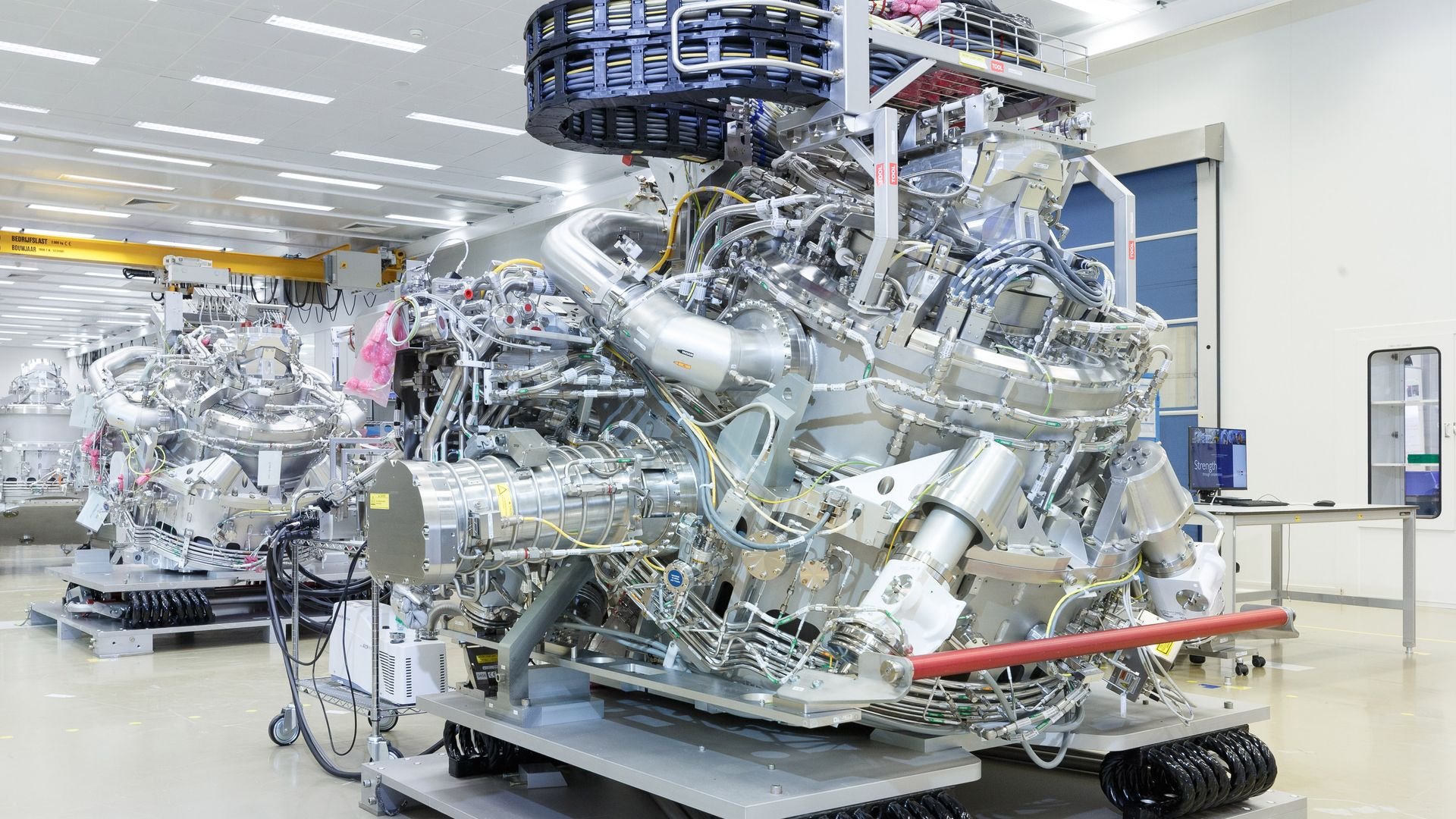

Every day, more than 10,000 of the brightest minds in R&D take on the challenge of improving the most advanced lithography systems in the world.

Our ability to innovate is crucial to our ongoing success, and that's why we continue to invest heavily in R&D: it’s the backbone of innovation. In 2020, we invested €2.2 billion in R&D (compared to €2.0 billion in 2019), and our total IP portfolio now exceeds 14,000 patents.

Patent portfolio

Product innovations

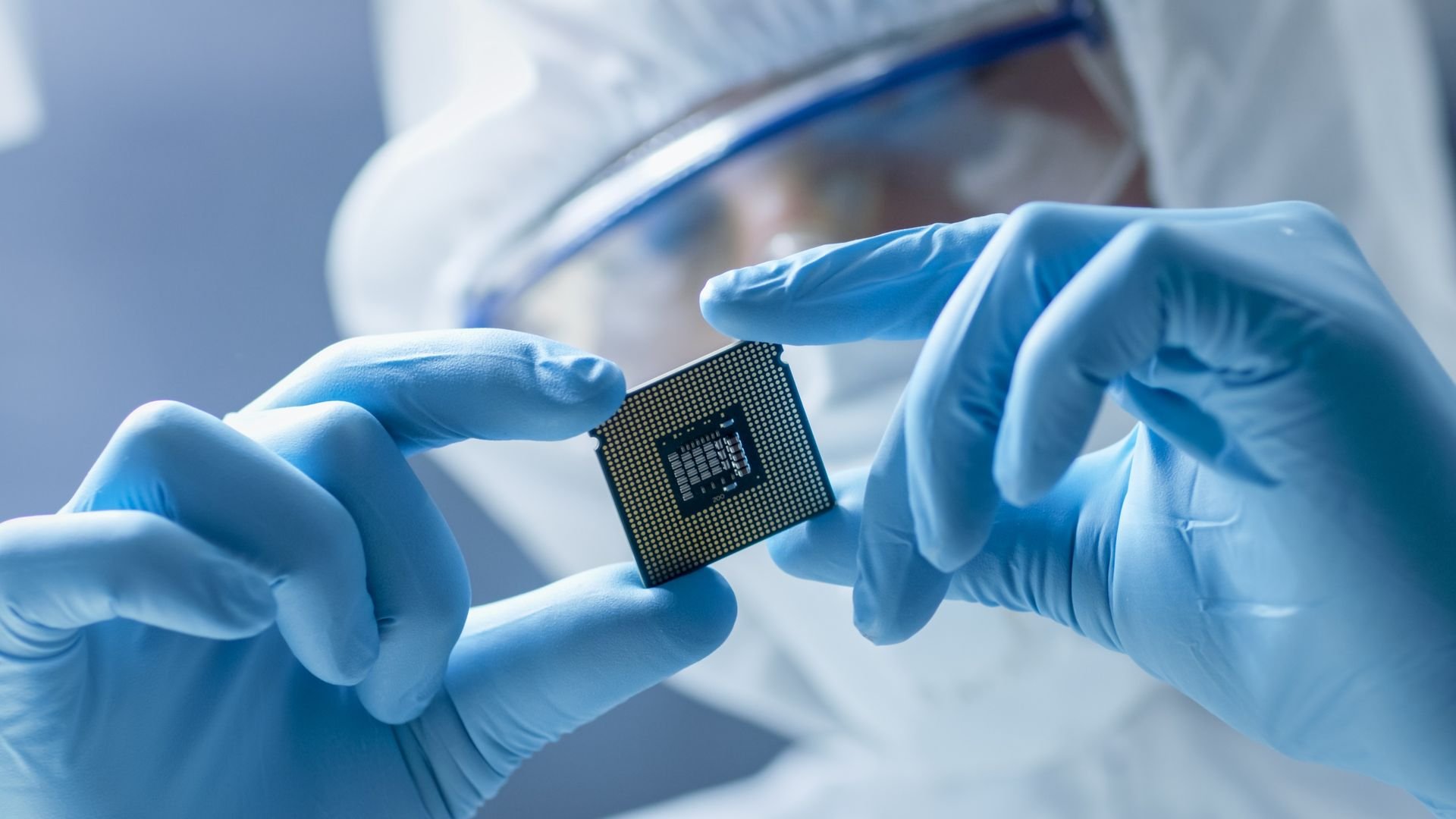

We continue to improve our lithography systems so that chipmakers can continue to shrink nodes. Integrating products across our portfolio enables us to offer holistic lithography solutions that help address the increasingly complex challenges of advanced chipmaking.

The ASML Technology Conference went online for the first time in its history and attracted a record number of attendants.

More than 16,000 employees and R&D partners across the globe were able to attend and listen to keynote speeches, gain insights about key technical projects, and connect with colleagues across all R&D competencies. What was lost in personal interactions was gained in the increased access available to people in all locations. Virtual elements are likely to be used in future conferences.

Startups and scaleups

To nurture innovation by new generations of technological talent, we actively support entrepreneurs and startups.

We have never forgotten that it’s our startup mentality – innovative, adaptable and purpose-driven – that has helped us grow into a tech industry leader. That’s why we eagerly foster entrepreneurship. We share our in-depth competencies and knowledge to support startups and scaleups, encouraging them to excel and grow. In 2020, we donated 1,550 hours of in-kind support to startups and scaelups.

Incooling combating waste heat

Established with ASML’s support at the start of 2019, Incooling uses cooling technology developed by CERN, the European Organization for Nuclear Research, to address one of the datacenter industry's major challenges: waste heat.

Incooling developed highly efficient cooling systems that will offer datacenters higher performance against substantially lower energy consumption. It has been recognized with the first CoSta Award for the most successful and impactful innovative collaboration between a corporate company and a startup.

Read more about this topic in the 2020 Annual Report

Scroll down to close this topic

and continue to the next

People

Adapt, improvise, overcome

Not only did our talented employees adapt to the new normal, they continued to deliver

Total employees (in FTE)

Nationalities working at ASML

Employee engagement score

Attrition rate

2020 year-end figures

We empower our diverse and talented employees so that they can be proud of themselves and of the company they work for.

In 2020, we faced an unprecedented global crisis that affected every facet of our lives and our business.

We had two clear priorities in our crisis response to the COVID-19 pandemic. Firstly to ensure the health and safety of our people and their families, and secondly to ensure business continuity.

Operationally we had to transform how we organized ourselves, our ways of working, and how we attracted new talent. We created COVID-secure workplaces for our employees, provided mental and physical health support, and stayed in close contact even when working remotely. Undoubtedly, this experience has made us stronger as a global team.

Despite the impacts of COVID-19, we were able to not only maintain, but grow our workforce.

Our total workforce rose to 28,073 FTE at year-end, including nearly 2,000 new payroll employees hired in 2020. We also welcomed nearly 1,600 employees from the acquisition of Berliner Glas in October. Our attrition rate of 3.8% – the percentage of employees leaving our company – decreased and is still significantly below that of our industry.

Our positive response to COVID-19 and our dedication to improving quality, well-being, inclusiveness and customer focus contributed to a high level of overall employee engagement. Our employee engagement rose to 80% in 2020 from 77% the previous year, which is 7% higher than our external global benchmark of 73%.

Employees across the company showed dedication and resilience to get ASML through the pandemic.

We facilitated a new self-sufficient mindset by updating our work from home policy and fast-tracked the provision of IT tools for remote working. Our customer support engineers were able to use our Basic Remote Equipment Support capability to solve machine issues remotely and continue to support customers.

Due to travel restrictions, we had to find new ways to train and support employees, especially our customer support engineers. We opened EUV technology training centers in South Korea and Taiwan to provide local training. And instead of ZEISS engineers traveling to service projection lenses at customer sites, we trained our local customer support engineers to do it. This increased our ability to cover critical service actions from less than 70% to more than 90%.

Below you can enable third party cookies. Your choice will be saved and the page will refresh.

To give our new colleagues the best possible start, HR teams and hiring managers across the globe pulled together to design a creative virtual onboarding experience.

In place of our usual Onboarding Day we found great virtual ways to make new colleagues feel welcome and part of the team. Veldhoven campus walking tours also went virtual and were gamified, which led to the development of other virtual games and business simulation tools.

Nearly 2,000 new colleagues joined ASML worldwide in 2020, and over 90% felt welcomed and supported by their manager and team members. And while most new colleagues started their new jobs from home, they reported that they still ‘felt part of ASML.’

With the demand for top-tier talent increasing every year, employer branding is vital.

Highly skilled people with a technical background are scarce. They are selecting their employer of choice, not the other way around. While we are doing well in employer brand rankings in the Netherlands, we have work to do in other regions. Digital channels are increasingly important in our efforts to reach, inform and engage potential candidates.

Employer brand ranking

- 4 Netherlands

- 22 Taiwan

- 24 South Korea

- 99 US

- 168 China

Universum rankings: engineering students

Attracting talent online

For example, in Taiwan, we livestreamed ASML Career Talk LIVE episodes on Facebook to introduce our company to target audiences. These were then picked up by Taiwanese media group Storm.mg for further coverage.

Read more about this topic in the 2020 Annual Report

Scroll down to close this topic

and continue to the next

Community

When our communities thrive, we thrive

In 2020, a collective, active role in society was more vital than ever before

Total spend on community outreach

COVID-19 donations

Donated by ASML Foundation

ASML Foundation projects supported

2020 year-end figures

As a global technology leader, we believe it’s our duty to be an active part of the communities we operate in – and we encourage our employees to do the same.

We're committed to supporting our communities during the COVID-19 (coronavirus) pandemic.

The pandemic has had a profound impact on our lives and the world we live in. We believe it’s our duty as global tech leaders to help in any way we can. That’s why ASML actively supports the coordinated actions of the national and regional authorities, as well as the efforts of other local organizations. In 2020 we donated a total of €2.7 million, comprising €1.2 million in medical support, €1.3 million in community support and €0.2 million in engineering support. See examples of our activities in the slideshow below.

Being part of a community means not only caring for our employees, but also looking out for those beyond our organization. We know that as a successful global tech leader, if the communities we operate in thrive, we thrive.

Our community engagement program is built around three areas where we have the power to create the most impact: culture, local outreach, and education. For example, in 2020 we announced the setting up of the Brainport Eindhoven Partner Fund and partnered with the Van Gogh Museum to present ‘Masterminds & Masterpieces’, a program of lessons uniting science and art.

ASML Foundation

Our independently operated charity funds projects to improve the lives of young people with inclusive, quality education. In 2020, the Foundation donated around €1 million, supporting 22 projects in 11 countries and helped projects convert physical classes to virtual learning. Over the last three years, it has reached over 17,000 children.

Read more about this topic in the 2020 Annual Report

Scroll down to close this topic

and continue to the next

Sustainability

On the long path to becoming circular

Working together with our value chain, we are accelerating our ambitions

Energy consumption

Renewable electricity

Waste generated per €m revenue

Material recycling rate

2020 year-end figures

From minimizing waste to maximizing the value of material, we take every step to lower our environmental footprint.

Energy and CO2 emissions

Our long-term renewable energy strategy is to achieve zero emissions across our operations.

In 2020, we achieved our target to run on 100% renewable electricity for our scope 2 energy consumption. Over the past ten years, we have reduced our energy footprint by 28% (realizing over 260 TJ savings), and our natural gas consumption has dropped from 382 TJ to 293 TJ. We aim to achieve direct energy savings of 100 TJ by 2025.

Our 2021–2025 Climate & Renewable Energy Sustainability program sets the targets of zero emissions from our operations (scope 1) and zero emissions from our energy use (scope 2). Realizing that the environmental impact of what we do goes beyond our operations, we are also committed to reducing the intensity of our scope 3 emissions (from the energy use of our products).

We have prioritized reducing the energy use of our EUV systems, which are now being used in high-volume manufacturing at customer sites. In 2020, we improved the energy efficiency (per wafer pass) of the NXE:3400C over its predecessor, the 3400B (from 13.08 to 9.64 kWh). By 2025, we aim to reduce the energy use per wafer of future-generation NXE systems by 60% compared to the 3400B.

Net emissions footprint

(Scope 1 & 2)

Value chain emission intensity per €m revenue

(Scope 3)

Reduce, Recycle, Re-use

We are committed to achieving a circular economy.

Reducing our environmental footprint and managing waste – both from our operations and products – is key to our circular economy approach and sustainability practices. Thanks to the modular design of our systems, we are able to refurbish and upgrade them across their life cycles. The majority of systems we have sold are still in use.

In 2020, we set up the dedicated Re-use department to accelerate the re-use of the parts, tools and packaging that result from upgrades or repairs. The department’s main objective is to establish an end-to-end process that enables this re-use, while reducing our total operational cost. It will also take the lead in setting up local and global repair centers, which will help drive material re-use.

Parts re-use value

PAS 5500 systems still in use

(from total ever sold)

We currently have local repair centers in South Korea and Taiwan and will be rolling out to China in 2021. Our ambition is to repair €100 million worth of parts by 2025.

In addition, several waste reduction projects in our operations were initiated by employees in 2020, including plastic recycling and working with reusable gloves in cleanrooms.

Responsible supply chain

We can’t improve sustainability alone. It is a shared responsibility between ourselves, our customers and suppliers.

We promote the Responsible Business Alliance (RBA) industry standards for sustainability in our supply chain. We screen suppliers on their sustainability performance, which includes labor, ethics, health and safety, and environmental criteria.

Around 80% of our supplier spend is covered by the RBA program, seeking to achieve continuous improvements. In addition, our procurement teams play an important role in our circularity ambitions, particularly with first-tier suppliers, aligning incentives for maximizing re-use value.

Total sourcing spend

Total suppliers

Read more about this topic in the 2020 Annual Report

Scroll down to close this topic

and continue to the next

Finance

Record sales in a unique year

We achieved €14.0 billion of net sales in 2020

Total net sales

Gross margin

Capital return

Earnings per share

All figures based on US GAAP

Through our industry-leading innovation and our long-term financial model, we expect to achieve sustainable growth for years to come.

Despite a global pandemic, 2020 was a growth year for ASML. Our net sales grew €2.2 billion in 2020 to €14.0 billion.

During 2020, we collaborated closely with our partners in the supply chain to ensure we could continue to manufacture and ship systems to our customers. The situation was very dynamic but we were able to manage the many challenges to limit the impact of COVID-19.

This strong year for ASML was driven by the continued advancement of EUV into volume production (both in Logic and Memory markets), the sustained strength in our DUV business and the increase in net service and field option sales.

Below you can enable third party cookies. Your choice will be saved and the page will refresh.

Our customers are increasingly confident in EUV technology, and we are delivering increased value with our innovations in DUV technology.

In 2020, we sold a total of 258 lithography systems, including 31 EUV systems. We also shipped the first NXT:2050i (ArF immersion) and NXT:1470 (ArF dry). The NXT:2050i includes several developments that deliver better overlay control at higher productivity levels than its predecessor. While the NXT:1470 is our first dry system on our successful NXT immersion platform, offering improvements in matched machine overlay, productivity and its footprint in the fab.

Gross profit as a percentage of net sales increased from 44.7% in 2019 to 48.6% in 2020.

The increase in gross margin was mainly attributable to increased EUV profitability and the growth in our service and upgrade sales. We continue to drive the profitability of our EUV systems and service business by delivering more value while optimizing our cost structure.

By limiting the impact of the pandemic, we kept up our strong financial performance and were able to continue to return capital through dividends and share buybacks.

The total capital return value of €2.3 billion was made up of €1.1 billion in dividends and €1.2 billion in share buybacks. Earnings per share grew to €8.49 in 2020 due to increased profitability, up from €6.16 in 2019.

We were able to return €1.2 billion of share buybacks despite the pause in 2020 (related to COVID). Our three-year share buyback program to purchase shares up to €6 billion within the 2020-2022 timeframe is unaffected.

We continue to invest in the future of ASML and significantly increased capital expenditures in 2020 to €1.0 billion.

This is in line with our roadmap to increase the value of EUV in high-volume manufacturing, the development of High-NA, as well as programs supporting holistic lithography solutions across our portfolio. We invested in the expansion and upgrade of facilities, prototypes, evaluation and training systems. This will continue into 2021, when we expect our capital expenditures to be approximately €1.5 billion.

Find out more about ASML and our 2020 results, financial statements, and how we manage risks, in our 2020 Annual Report.

Back to top of highlights

Or visit the 2020 Annual Report main page