Technology

A 20-year dream becomes reality

2019 will be remembered as the year our EUV technology entered high-volume chip manufacturing at customer sites

Wafers per hour on multiple EUV NXE:3400C

2019 year-end figures

R&D investment

Invested in R&D partners

Hours of support to high-tech startups & scaleups

Our highly differentiated solutions provide unique value drivers for our customers and ASML

The breakthrough of EUV

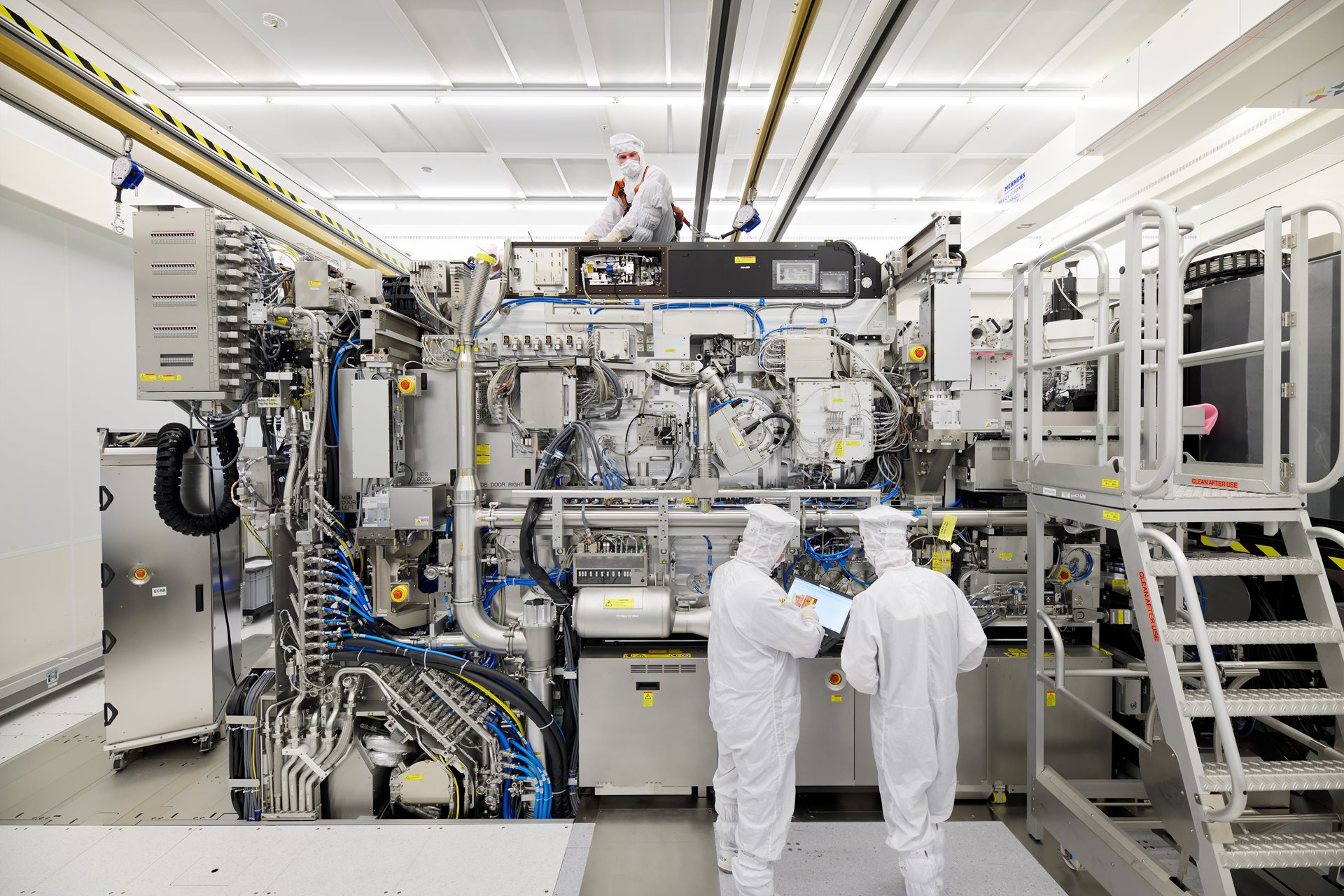

Extreme ultraviolet (EUV) lithography has progressed into high-volume manufacturing of commercial microchips – the result of a 20-year development journey that involved both ASML and all our stakeholders.

Customers have introduced their first EUV-manufactured devices, and they are mentioning EUV in their product announcements.

First NXE:3400C shipped

Our latest EUV system, the NXE:3400C, has proved significantly more reliable and more productive than the previous system. With a 35% increase in throughput, from 125 wafers to 170 wafers per hour, we demonstrated over 2,000 wafers per day under customer DRAM Memory conditions.

EUV systems shipped in 2019

Total EUV systems in the field (NXE:3400)

High-NA EUV platform in development

With EUV firmly established on our customers’ roadmaps, we see a clear path for the continuation of Moore’s Law well beyond the current decade. To support that, we are developing a High-NA EUV platform that will enable next-generation geometric shrink to the 2-nanometer node.

About EUV

EUV lithography, a technology entirely unique to ASML, uses light with a wavelength of 13.5 nanometers. This wavelength is almost 14 times shorter than DUV, the other lithography solution used in advanced chipmaking. Shorter wavelengths mean smaller transistors, which mean more advanced microchips. Peek inside one of these systems below to find out more.

How does EUV work?

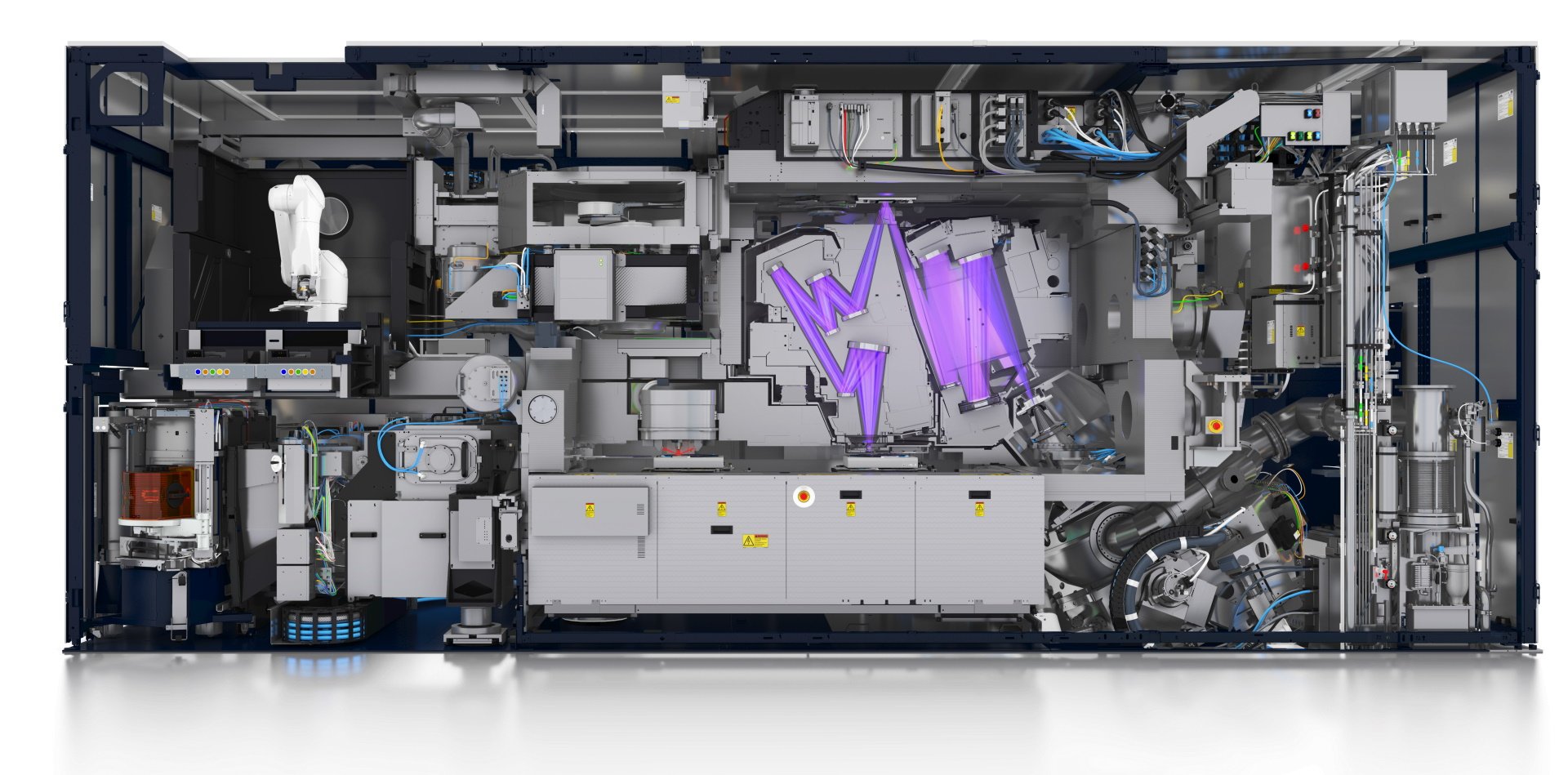

Explore inside an NXE lithography system

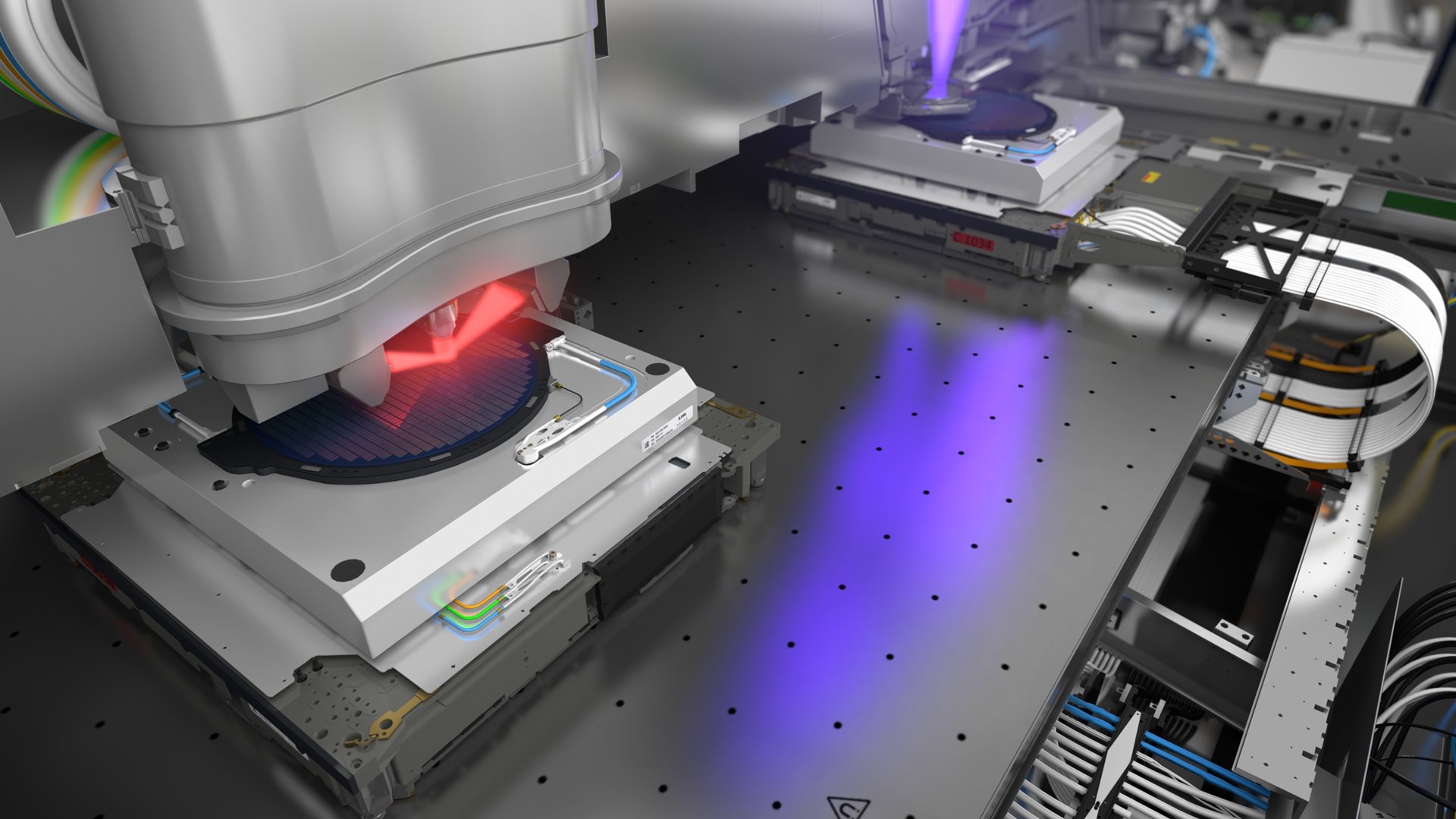

Light source

Optical column

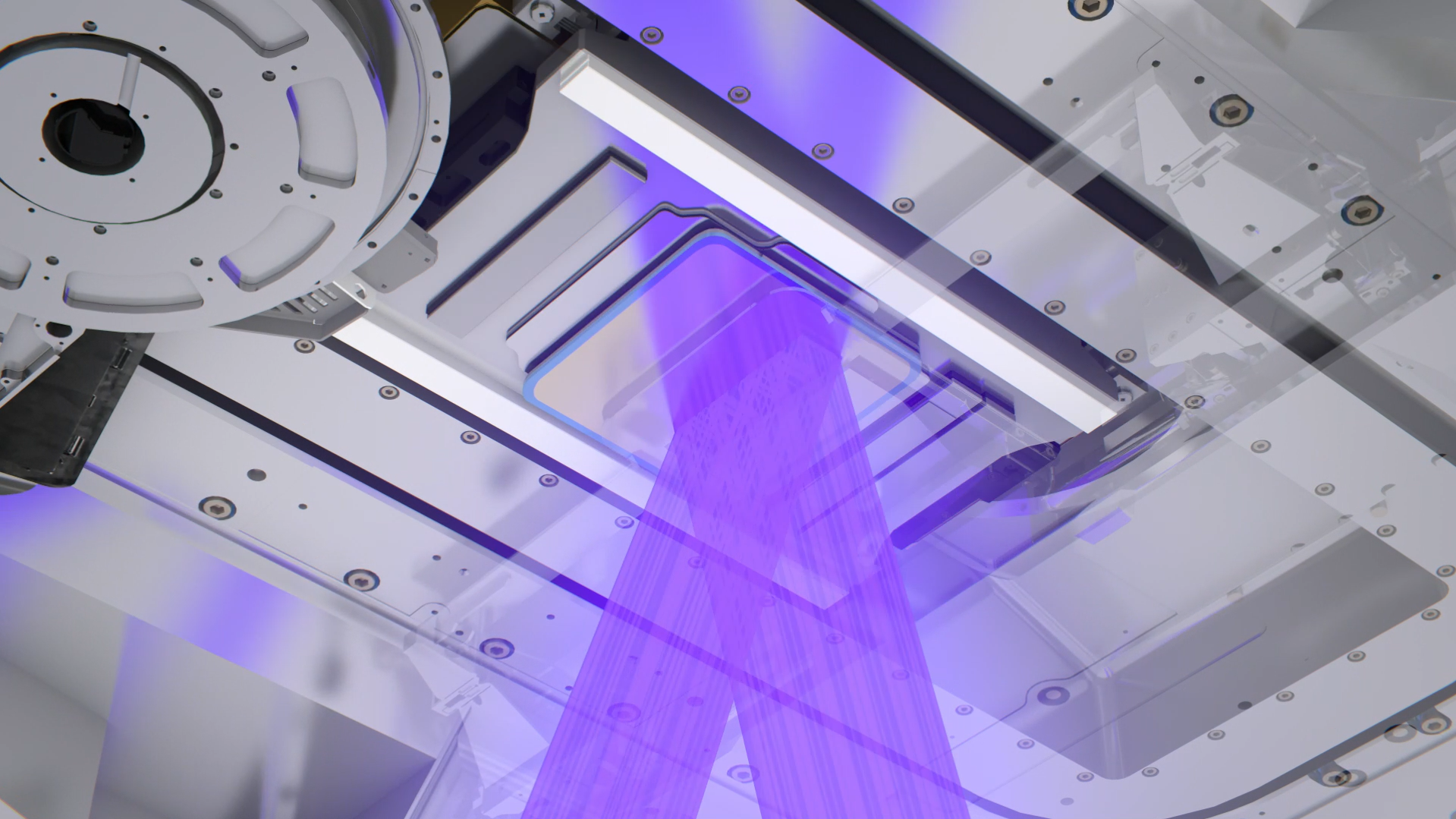

Reticle

Vacuum chamber

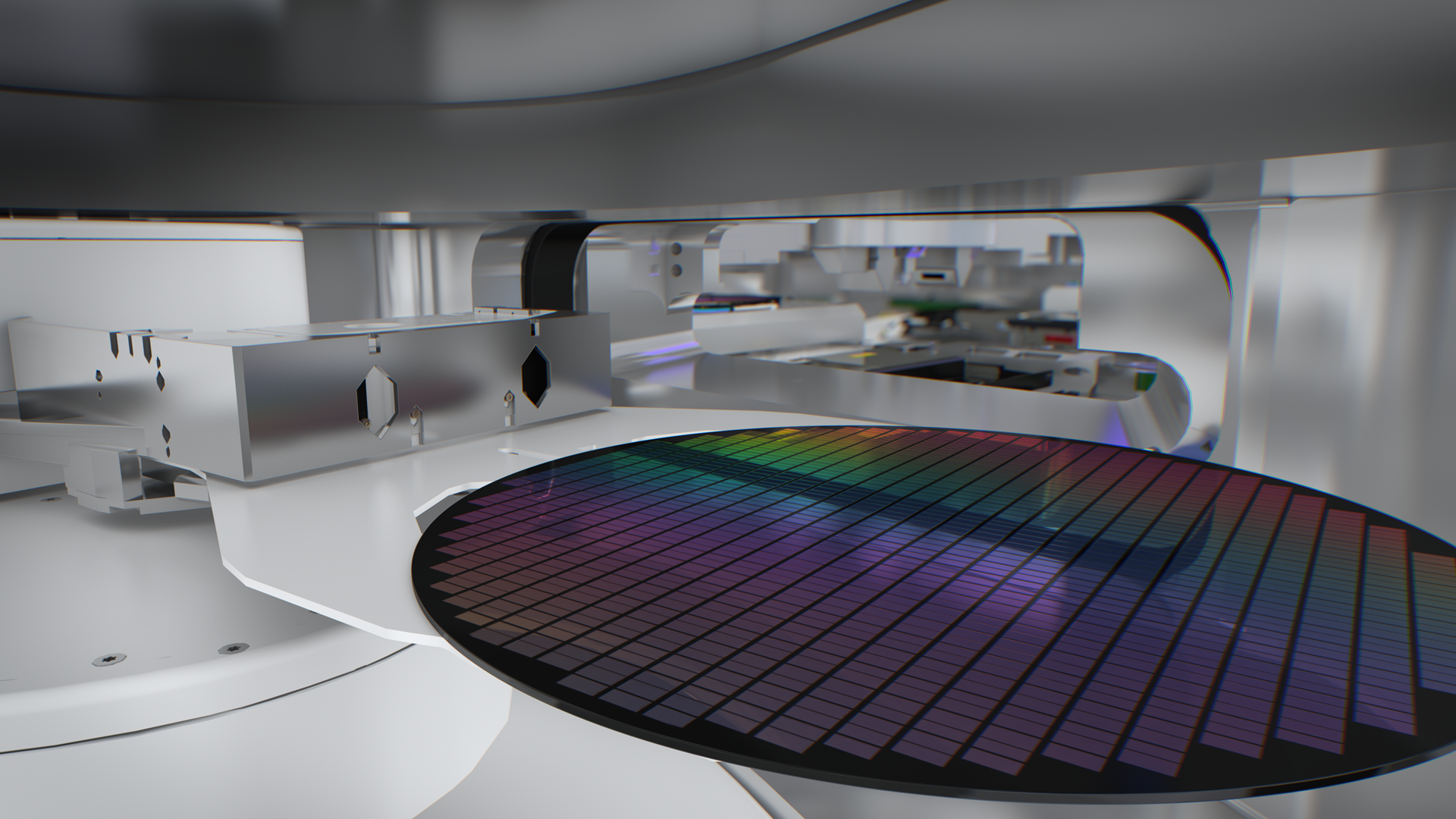

Wafer handler

Wafer stage

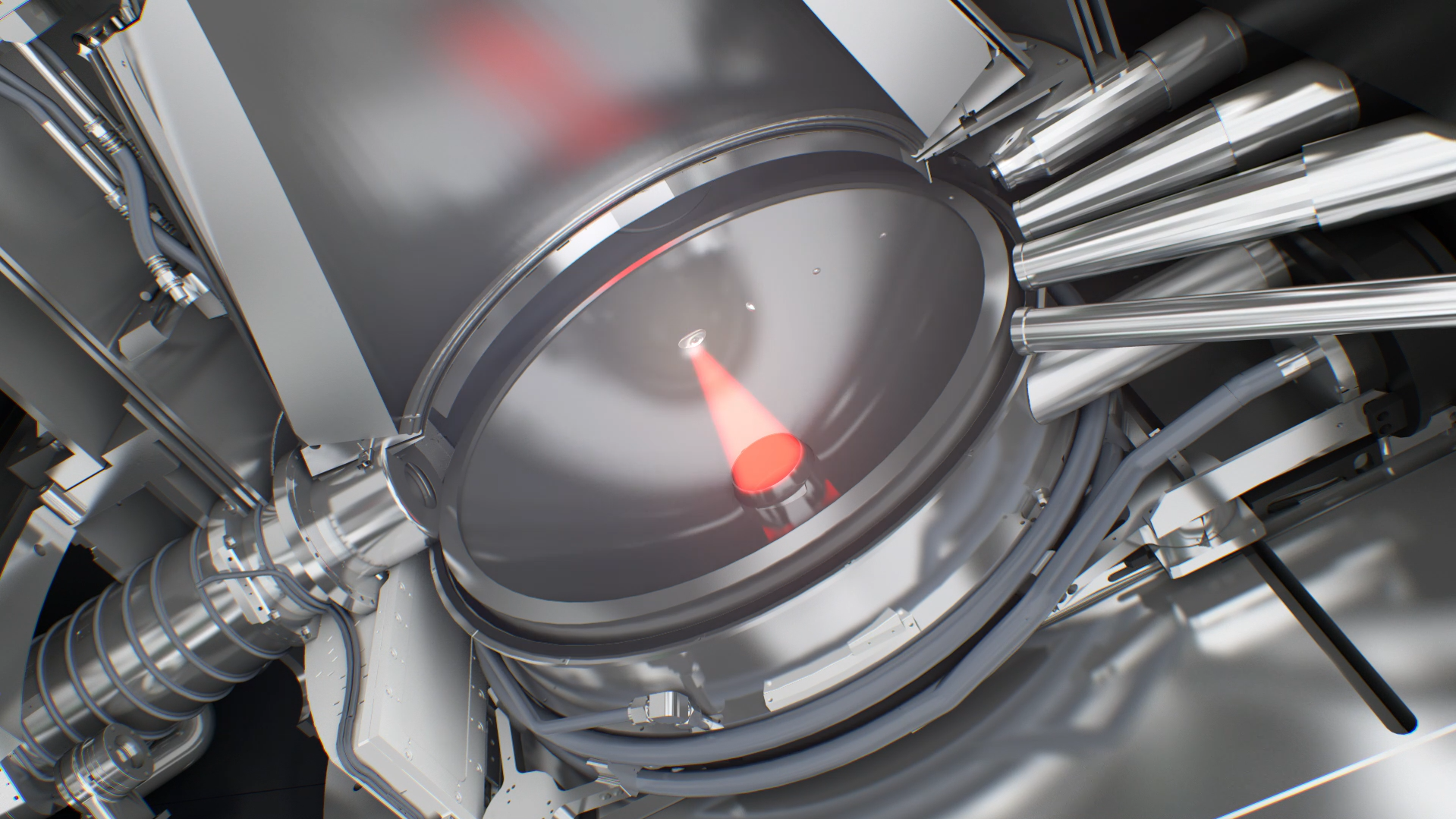

Light source

To generate EUV light, CO2 laser fires two separate laser pulses at a fast-moving drop of tin. This vaporizes the tin and creates EUV light. It does this up to 50,000 times per second.

Read more about light in lithography.

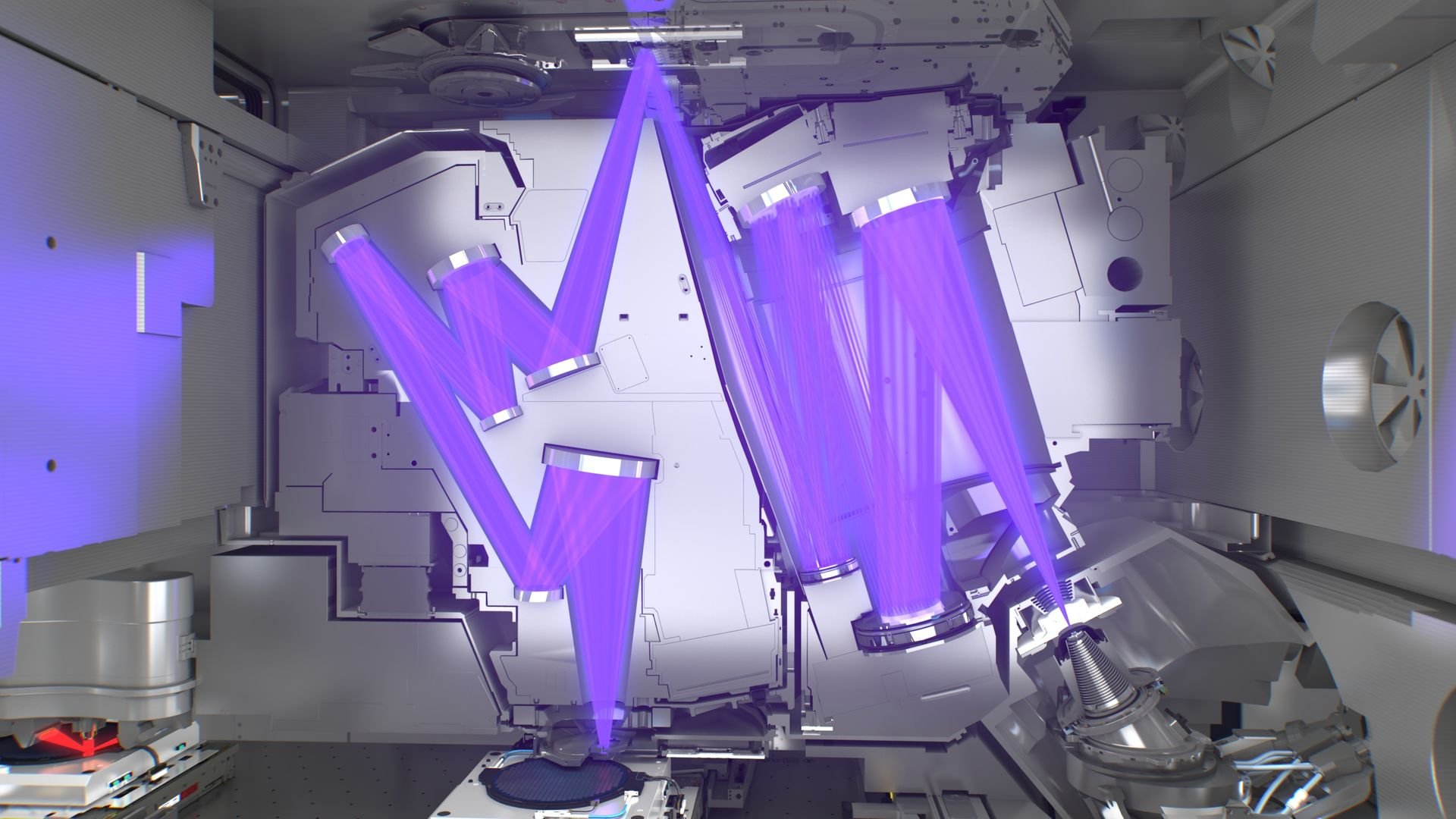

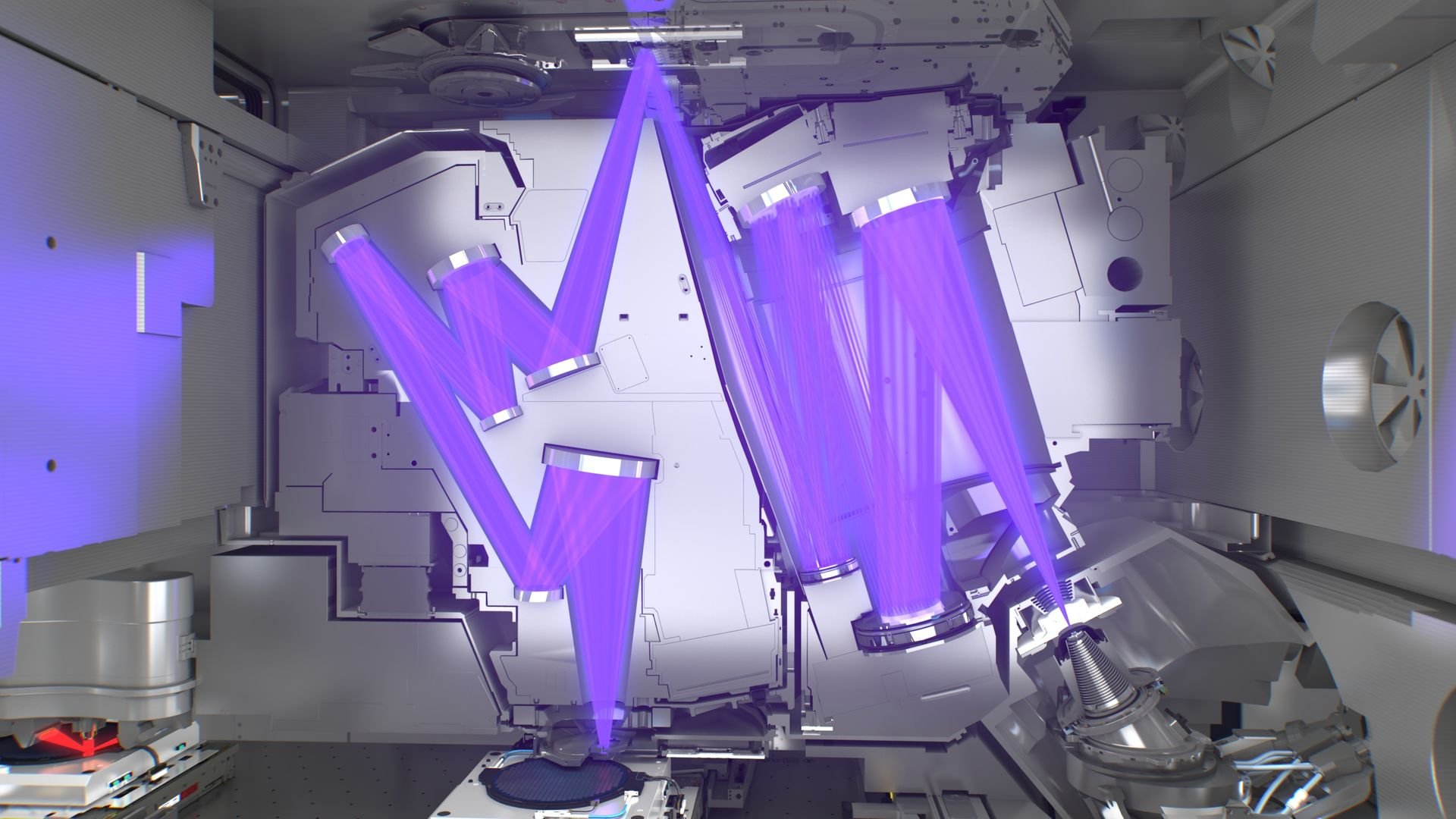

Optical column

EUV systems use several multilayer mirrors instead of lenses to guide the EUV light to the wafer, shrinking the reticle pattern by a factor of four.

Reticle

Reticles contain the chip pattern to be printed on the wafer. In EUV, reticles are multilayer reflectors that use interference to reflect light from the pattern.

Vacuum chamber

EUV light is absorbed by everything, even air. So the whole light path and everything the light interacts with – from source to wafer – must be in high vacuum.

Wafer handler

Precision robot arms transfer wafers in and out of the system’s vacuum environment through an air lock, operating within a positioning accuracy of 25 µm and a uniform surface temperature within 2 mK.

Wafer stage

The wafer stage positions the wafer to within a quarter of a nanometer for each exposure, checking and adjusting 20,000 times per second.

We invest heavily in R&D to ensure we keep innovating at the same pace as our customers. We spent €2.0 billion on R&D in 2019, a big increase over the €1.6 billion invested in 2018. Over the last five years, our R&D investments have reached €7.0 billion.

Our patent portfolio has increased more than 15% over the last five years and now includes more than 13,700 patents over multiple jurisdictions.

IP & developed technology value

Patent portfolio

Our innovation ecosystem

Collaboration is the key to success at ASML. We progress and achieve our goals through partnerships in an innovation ecosystem. We work closely with our customers to develop today what they need tomorrow.

Similarly we work closely with a network of world-leading external partners and research organizations and co-develop with some suppliers. We rely on an extensive supply base of around 790 product-related suppliers plus around 4,200 non-product-related suppliers.

Our investments extend to our partners in R&D, including some of the product-related suppliers, such as Carl Zeiss SMT, who innovate alongside us and develop system parts or modules. In 2019, our total investment in R&D partners was €500 million.

Nurturing young tech companies

We utilize the expertise within ASML to foster entrepreneurship in the high-tech Brainport region of the Netherlands. In 2019, we provided approximately 1,300 hours of support to high-tech startups and scaleups. The total value of our in-kind support was around €0.4 million.

People

Empowered to thrive

With nearly 25,000 employees on three continents, we focus on helping them all reach their full potential

Total employees (in FTE)

2019 year-end figures

Nationalities working at ASML

Jobs created

Attrition rate

Our employees are crucial to our success and help us push the limits of technology

In the past five years, we have created nearly 10,000 jobs in the communities where we operate. In 2019, about 40% of our workforce had been at ASML for fewer than two years.

Employee engagement is critical to our long-term success. We want to enable our people to develop their talent, feel respected and operate to the best of their abilities.

Boosting engagement depends on a wide variety of factors and activities. In 2019, we put special focus on offering career development opportunities, investing in a strong talent pool as well as updating and improving our employee onboarding experience.

Culture and values

The strong growth in our total workforce, the large number of new employees, and the evolution of the company also drove us to review what we stand for as a company. We invested in shaping and strengthening a common company culture, where shared means and our values prevail. Our values – Challenge, Collaborate and Care – are at the heart of this investment.

Measuring engagement

We redesigned our employee survey and renamed it ‘we@ASML’. The new survey will be carried out annually and is better benchmarked, making it easier to compare the results with other companies.

The 2019 results of the we@ASML employee survey showed that our employees are highly engaged, with

an engagement score of 77%, comparing favorably to the external benchmark of 73%.

The survey registered a strong level of trust within teams. Our employees also expressed their views on areas for improvement, such as some inefficiencies, which may well be the result of our fast growth. Resolving these will be a focus for us in the coming years.

Attrition rate improves

After a few years of modest increase, we were also pleased to see our attrition rate (the percentage of employees leaving our company) decrease in 2019 to 4.3% (versus 4.7% in 2018), which is significantly below that of our industry.

Sustainability

Shaping a sustainable future

Our new sustainability strategy includes targets to become carbon neutral in operations and minimize waste

Renewable energy consumption

2019 year-end figures

CO2 Scope 1 and 2 net footprint decreased

Waste created per €m revenue

Waste recycled

We aim to invent, develop and manufacture our products in a more environmentally friendly way

Our new strategy for the years 2019–2025 focuses on five sustainability areas.

It will help us ensure a sustainable business and long-term value for our stakeholders, as well as shape a sustainable future and contribute to the United Nations Sustainable Development Goals.

Sustainability strategy

Five focus areas

Energy and CO2 emissions

Our ambition is to achieve zero emissions across our operations. We are committed to decreasing our greenhouse gas (GHG) emissions and reducing our carbon footprint across our operations as well as in our value chain.

We are enhancing the energy efficiency of our buildings, shifting to renewable energy, and reducing emissions in our value chain where possible. In 2019, we used 97% renewable electricity across our operations, and we’re on track to achieve and maintain our ambition of 100% renewable electricity in 2020.

We reduced our combined net Scope 1 and Scope 2 CO2 footprint by 32.5%. This includes direct (-3% Scope 1) and indirect (-63% Scope 2) emissions from our operations. Savings were realized by improved technical installations and production processes at ASML. Other improvements included switching to LED lighting in our offices and recovering exhaust heat.

Our ongoing challenge is to meet our customers’ expectations of increasing the performance of our products while also reducing their energy consumption.

Our new strategy includes ambitious targets to reduce waste, increase recycling and encourage reuse.

New waste targets

Our level of recycled waste, or material recovery, increased to 80% in 2019 and we’re working towards 85% by 2025. In addition, we want to reduce the amount of waste per revenue (yearly). This will require a change in mindset, and we must embed circularity in our way of working and thinking.

We have a number of waste management initiatives, including flexible cleanrooms and our Return4Reuse and As-New programs. In 2019, around 1.5 million kilograms of materials were received for reuse through the Return4Reuse program, preventing them from ending up as waste.

The modular design of our products enables us to upgrade those in use at our customers’ sites to a higher performance level without replacing the entire product. We also refurbish and upgrades our older lithography systems to a higher performance level to extend their lives.

System lifetime

A well-maintained ASML lithography system can last for decades, and almost every lithography system that we’ve ever shipped is still in use at a customer fab. Once older systems (such as the PAS 5500) are replaced by newer generations, they are refurbished and given a new lease of life in a fab where the manufacturer requires comparatively less sophisticated chips (such as accelerometers or radiofrequency chips).

ASML PAS systems still in use

Of total ever sold

Systems refurbished to extend lifetime

Total of last 5 years

Veldhoven campus

Sustainable redesign is a key activity as we expand our campus in Veldhoven, the Netherlands, aiming to reduce the environmental footprint of every square meter and limit waste. We are also striving to achieve a BREEAM level of ‘excellent’. Any new buildings we develop will be sustainable, with materials being reused and as little as possible thrown away during the building process.

Community

Moving forward, giving back

We continue to help the world progress, in more ways than one

Total spend on community outreach

2019 year-end figures

Projects supported through ASML Foundation

Employee volunteer hours

Students reached

Being part of a community means not only caring for our own employees but looking out for those beyond our organization

We combined our sponsoring and community engagement programs to enhance the ways we engage with and support the community. Our donations focus on working with our partners to reach out to our communities, not on brand awareness.

Our community relations program is built on three pillars:

In 2019, the total amount of cash commitments and in-kind support that ASML spent on charities, community involvement, organizations and our own ASML Foundation was around €5 million.

Independently operated ASML Foundation is our charity of choice. It funds projects to improve the lives of young people with inclusive, quality education. In 2019, the Foundation donated €0.9m, supporting 17 projects in 7 countries.

We encourage our employees to contribute one day per year as volunteers during paid work hours.

We contributed more than 7,600 hours of volunteer work in 2019. Among our volunteering activities, we paint shelters, repair playgrounds, work in nature, clean beaches or take elderly people out for a day of fun. Groups of employees also get together to organize food drives or to make sure that children from financially disadvantaged homes receive Christmas presents.

Coastal cleanup

Coastal cleanup Food banks

Food banks Angel Tree initiative

Angel Tree initiativeA key part of our community focus is on STEM (science, technology, engineering and math) education. As a global tech leader, we have a responsibility to prepare people for an increasingly digital future.

For many years we have encouraged employees to be ASML technology ambassadors. These ambassadors give guest lectures at primary and secondary schools and technology events around the world so that they can pass on their passion for technology and science to the next generation. We also promote technology among young people and students to raise the profile of the career prospects in our sector. In 2019, we reached a total of 9,000 students worldwide.

Finance

A record sales year

ASML achieved €11.8 billion in net sales in 2019

Net sales

Based on US GAAP

Gross margin

R&D expenses

Earnings per share (basic)

Over half the net value of our bookings now comes from EUV systems highlighting strong demand for our unique technology

2019 was a year of growth for ASML with €11.8 billion in net sales, setting another record for us. Major innovation drivers such as artificial intelligence, 5G, high-performance computing, autonomous driving and big data are enabling new end-user applications. These applications require a larger number of high-performance Logic chips, fueling demand for leading-edge nodes.

Due to our continued growth and the number of our products now in the field, our installed base business is gaining momentum and was worth over €2.8 billion in 2019.

Below you can enable third party cookies. Your choice will be saved and the page will refresh.

We sold a total of 229 lithography systems in 2019. Our DUV business remains strong and far greater in volume, but over half the value of our net bookings now comes from EUV systems. We shipped around 50% more of our YieldStar metrology systems than last year, driven by demand in the lead-edge Logic market.

Of the 26 EUV systems we shipped, 9 were our latest model, the NXE:3400C. This system delivers increased productivity of over 35% as well as significant improvements in availability, helping our customers drive down the production cost per wafer.

We continue to be focused on the long term, with significant and strategic investments in R&D and operational infrastructure.

Our R&D spend increased significantly in 2019, reaching €2.0 billion. Our focus is on bringing our current EUV technology to the maturity level of our DUV systems to meet our customers’ high-volume manufacturing requirements and developing the next-generation EUV technology: High-NA. In addition to EUV developments, we continue to invest in our DUV technology and our Metrology & Inspection product portfolio, which includes our NXT:2050 and our multibeam inspection system.

Our capital expenditure is focused on building the facilities we need to develop and manufacture our new technologies and support future growth opportunities.

In 2019 we introduced an interim dividend payment, aligning cash distributions closer to our cash flow pattern. ASML aims to distribute a dividend that will grow over time, paid semi-annually. The 2018–2019 share buyback program for up to €2.5 billion was not completed for the full amount. In January 2020, we announced a share buyback program for up to €6.0 billion, to be executed within the 2020–2022 time frame.