Wilton at a glance

With over 3,000 employees, ASML Wilton is an important competency center, specializing in critical technologies that advance the performance of our lithography and metrology systems. It’s also our only in-house optical fabrication site.

0123456789

0123456789

0123456789

0123456789

Year established

0123456789

0123456789

0123456789

0123456789

Year acquired

0123456789

k

+

Employees

2022 annual figures

0123456789

.

0123456789

y

r

s

Average employee tenure

2022 annual figures

Specialties

Find your passion at ASML WiltonOur technology in Wilton

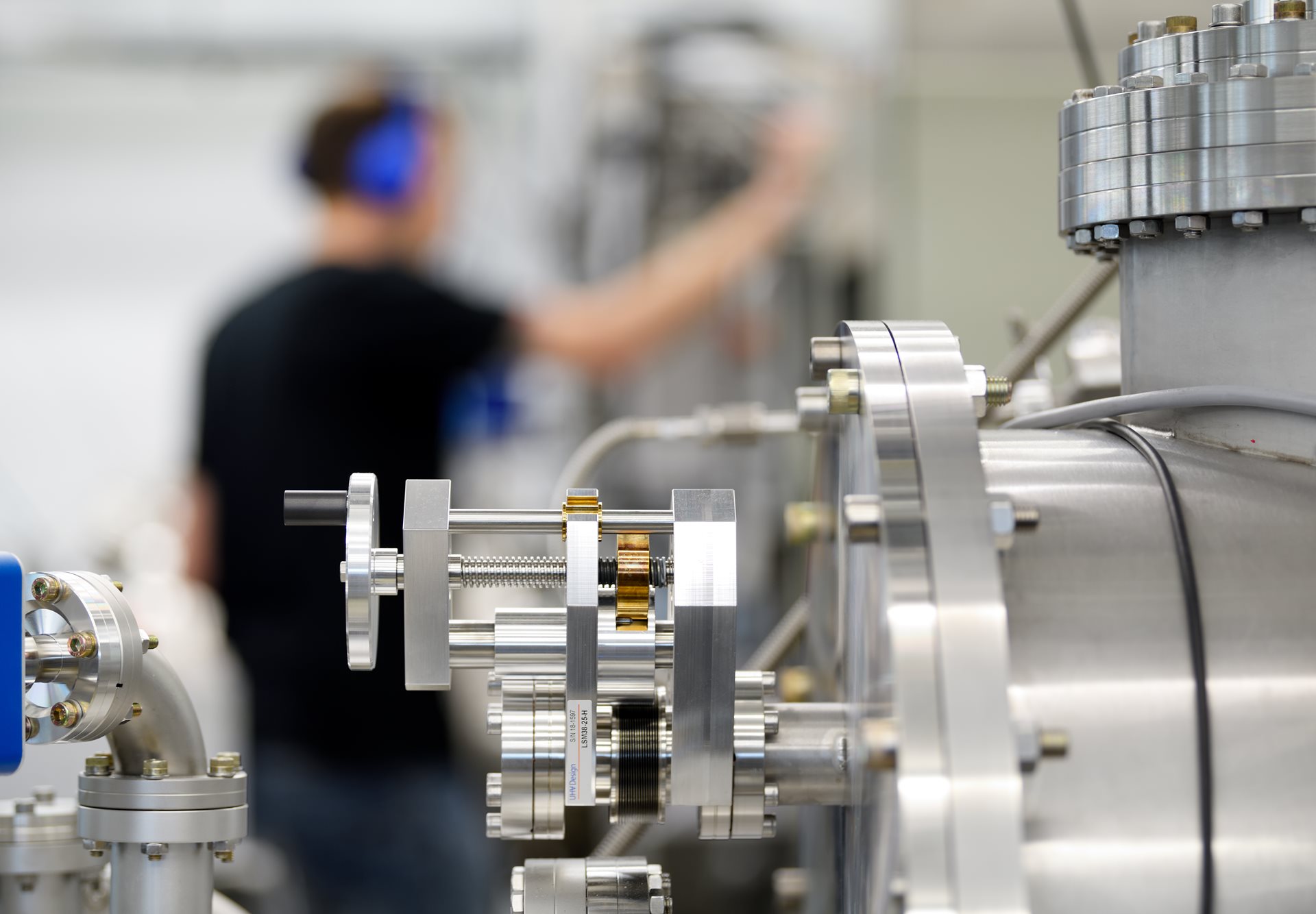

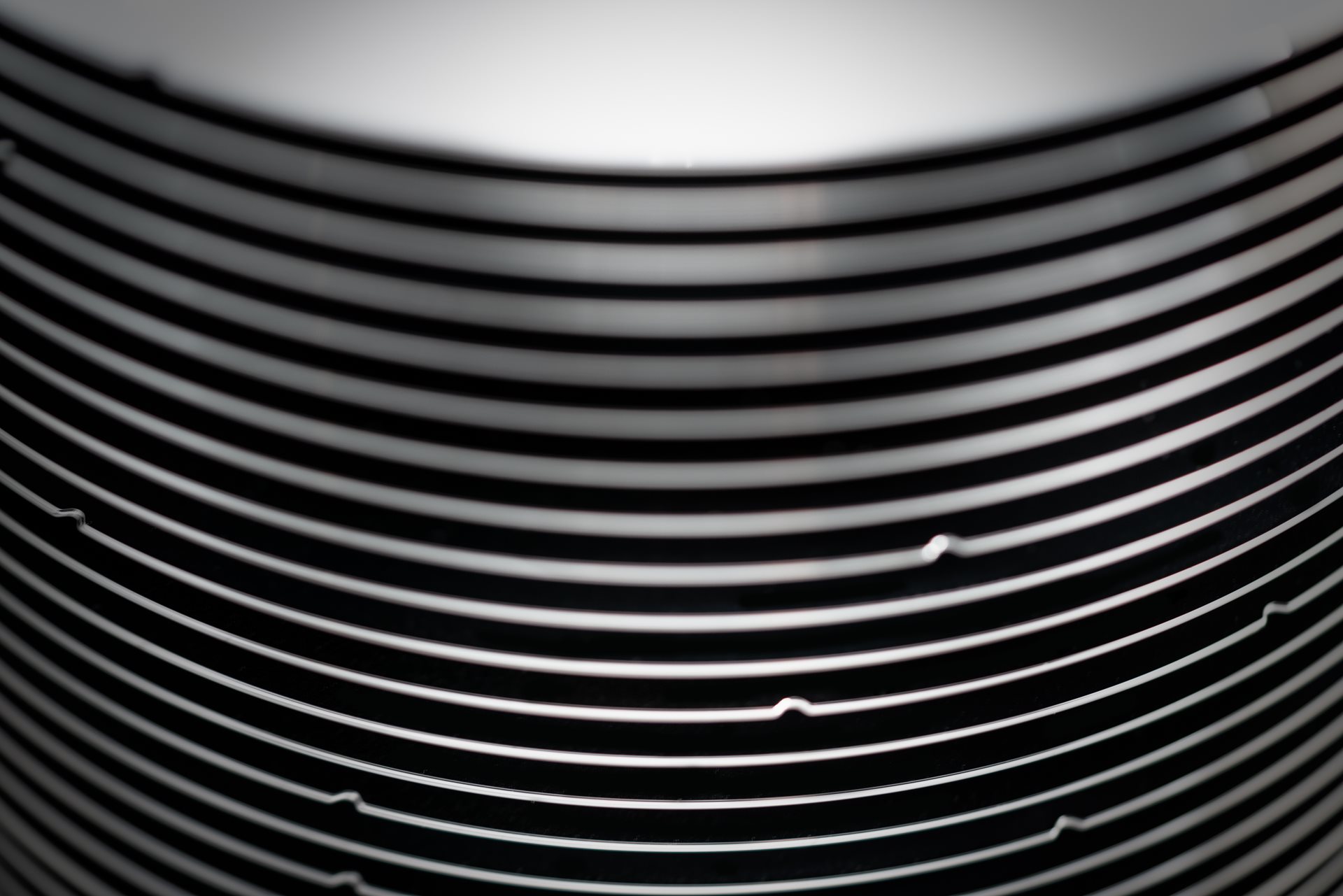

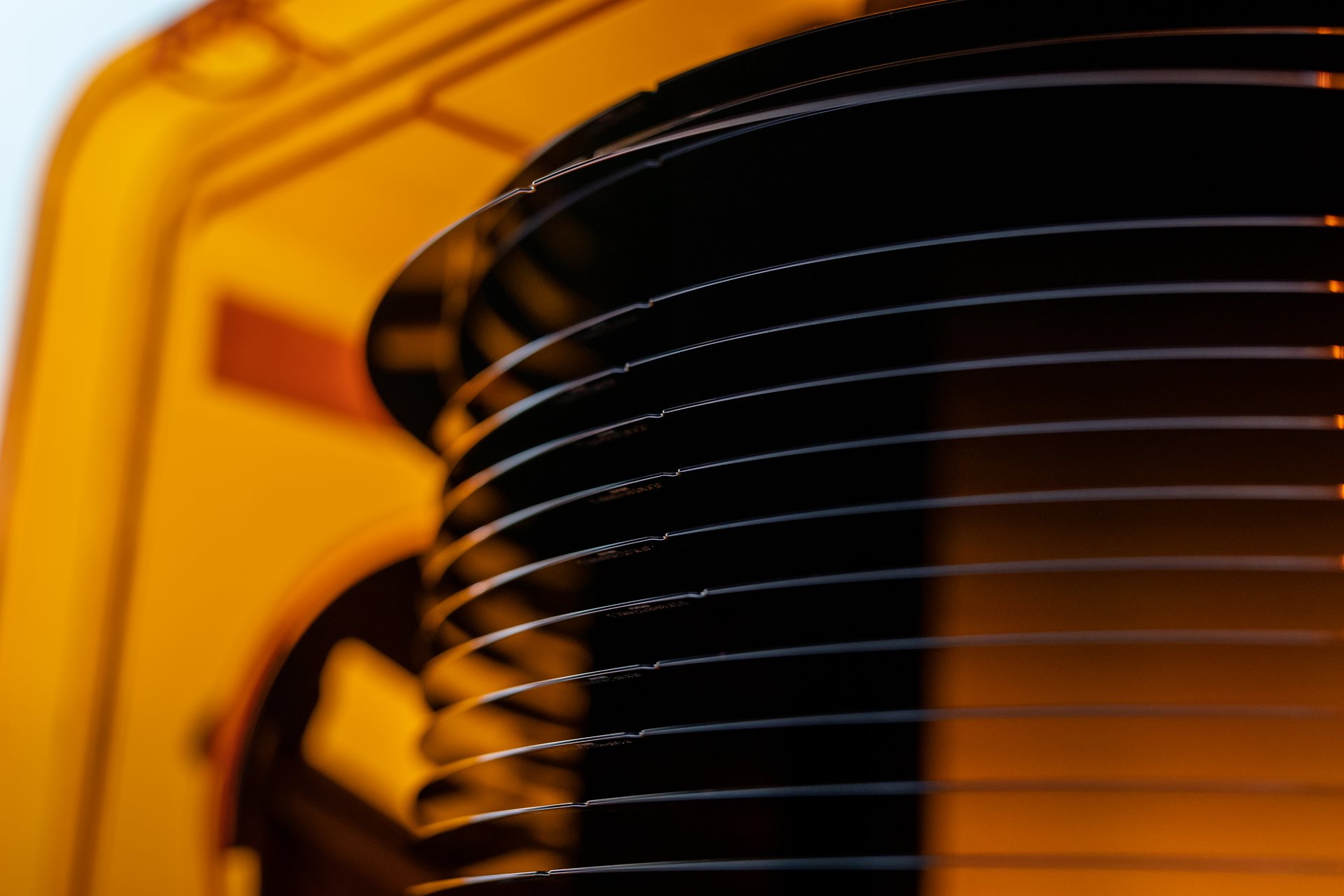

In Wilton, we work on mechatronics modules, optics, and optical sensors and measurement systems that are critical to both our lithography machines and our metrology and inspection systems.

Read more

Working and living in Wilton

Located in southwestern Connecticut, Wilton boasts a charming environment of historic buildings, beautiful wooded areas and serene coastlines. The region offers upscale residential communities and amenities and is also near thriving global corporations and metropolitan centers.

Read more

7 things you didn’t know about ASML’s history in Wilton, Connecticut

From Micralign to EUV lithography, ASML’s site in Wilton, CT, has deep roots in the semiconductor industry.

Meet Lana Volchematieva, mechanical design engineer

Meet Rachel Harrington, cleanroom technician

Meet Roger Da Mata, electrical engineer team lead

Meet Timea Kane, senior design engineer