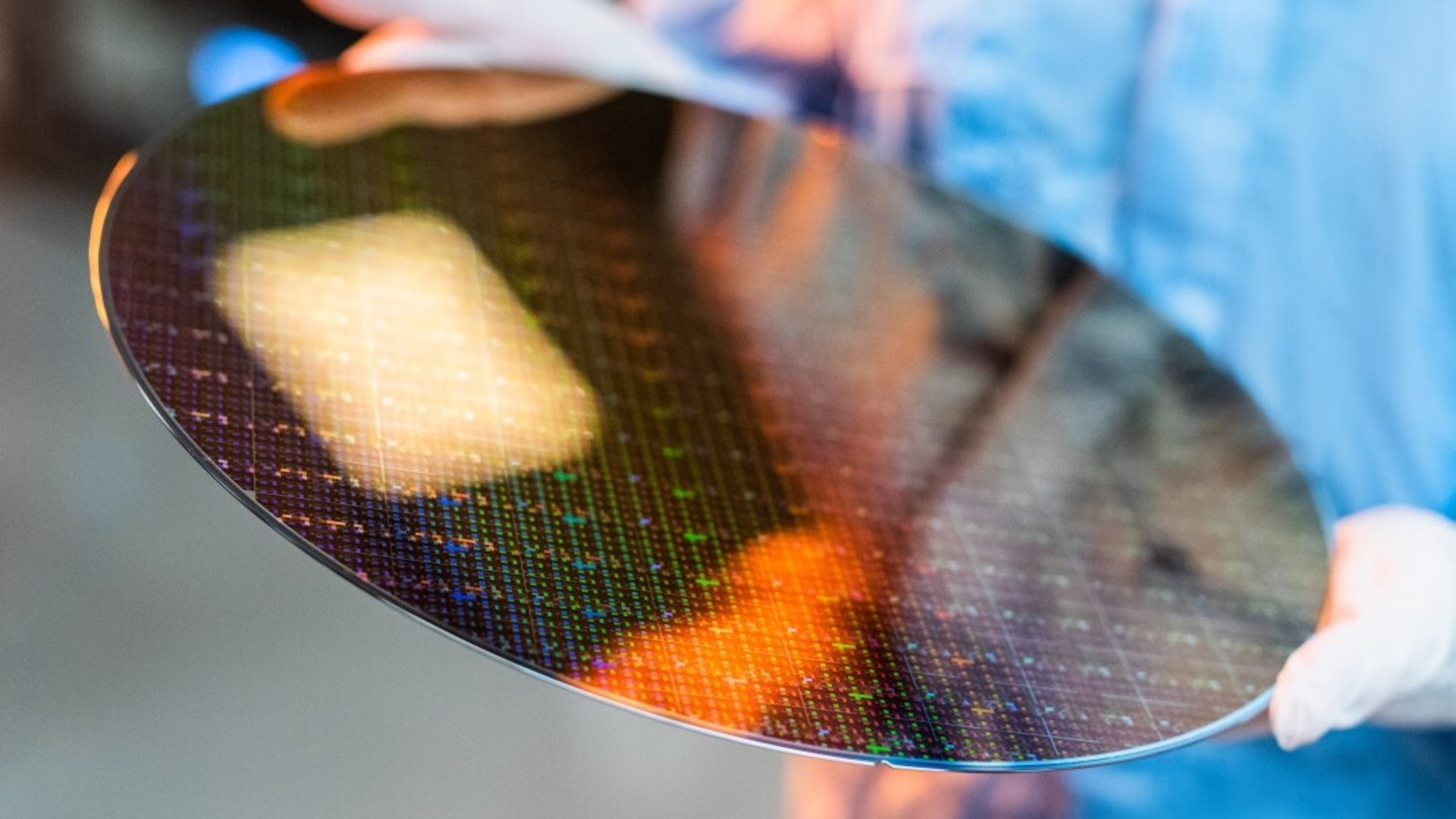

Electron optics is fundamental to ASML’s electron-beam (e-beam) systems. Chipmakers use ASML’s e-beam metrology &and inspection systems to quickly and accurately measure chip pattern quality before and during high-volume production.

Working in electron optics at ASML

At our Silicon Valley location, people from many different professional backgrounds work together in collaborative, supportive teams to push e-beam technology to new limits. Here, physics experts can turn their passion for modeling into the next generation of semiconductor production technology.

In the engineering department we have three teams working in electron optics. The electron optics simulation team proposes and models innovative design concepts, meticulously tweaking their designs to meet tight performance constraints. The design team will implement the proposed models from simulation team and turn them into real modules. After that the testing and integration team will integrate the modules, test and qualify the modules and support the system level integration. The three teams collaborate closely everyday to develop the advanced electron optics systems.

The team also works closely with other R&D departments to improve our systems’ performance by developing novel simulation tools for accurate modeling of a variety of critical scanning electron microscope (SEM) processes.

Electron optics in our technology

Our HMI e-beam metrology and inspection systems go hand in hand with our lithography systems to help chipmakers improve yield and produce faster, more powerful microchips.

E-beam metrology and inspection systems are essentially scanning electron microscopes (SEMs) that can locate, imaging and analyze individual chip defects amid millions of tiny, printed patterns.

ASML’s multibeam inspection systems are the first machines to be able to split one electron beam into multiple beams to increase inspection throughput

Career tracks in electron optics

Be an electron optics concept designer or mechanical designer, staying one step ahead of new development trends in e-beam metrology and inspection.

Use simulation tools to validate concepts, measure performance and support the testing and integration of our e-beam metrology and inspection systems.

Focus on performance improvement, feeding valuable data from scanning electron microscopes back to design teams.

Gain the opportunity to develop into leadership roles, including technical experts (‘architects’), project leaders and people managers.

Meet Yu Gong, senior optical sensing engineer

Learn about how ASML’s e-beam metrology and inspection systems help chipmakers navigate at the nano scale.

Meet Peter Casey, senior electron optics engineer

Casey and his team design optics for electron microscopes that are optimized for use in high-volume manufacturing.

ASML Fellows: giving technical experts the recognition they deserve

Originally educated in photon optics, Weiming Ren has become a renowned expert in electron optics. She is considered ASML’s leading authority on single- and multi-beam electron optics design. She was named a Fellow in 2018.

Become a pioneer in this leading-edge field

Want to be alerted for new jobs?

Create job alert