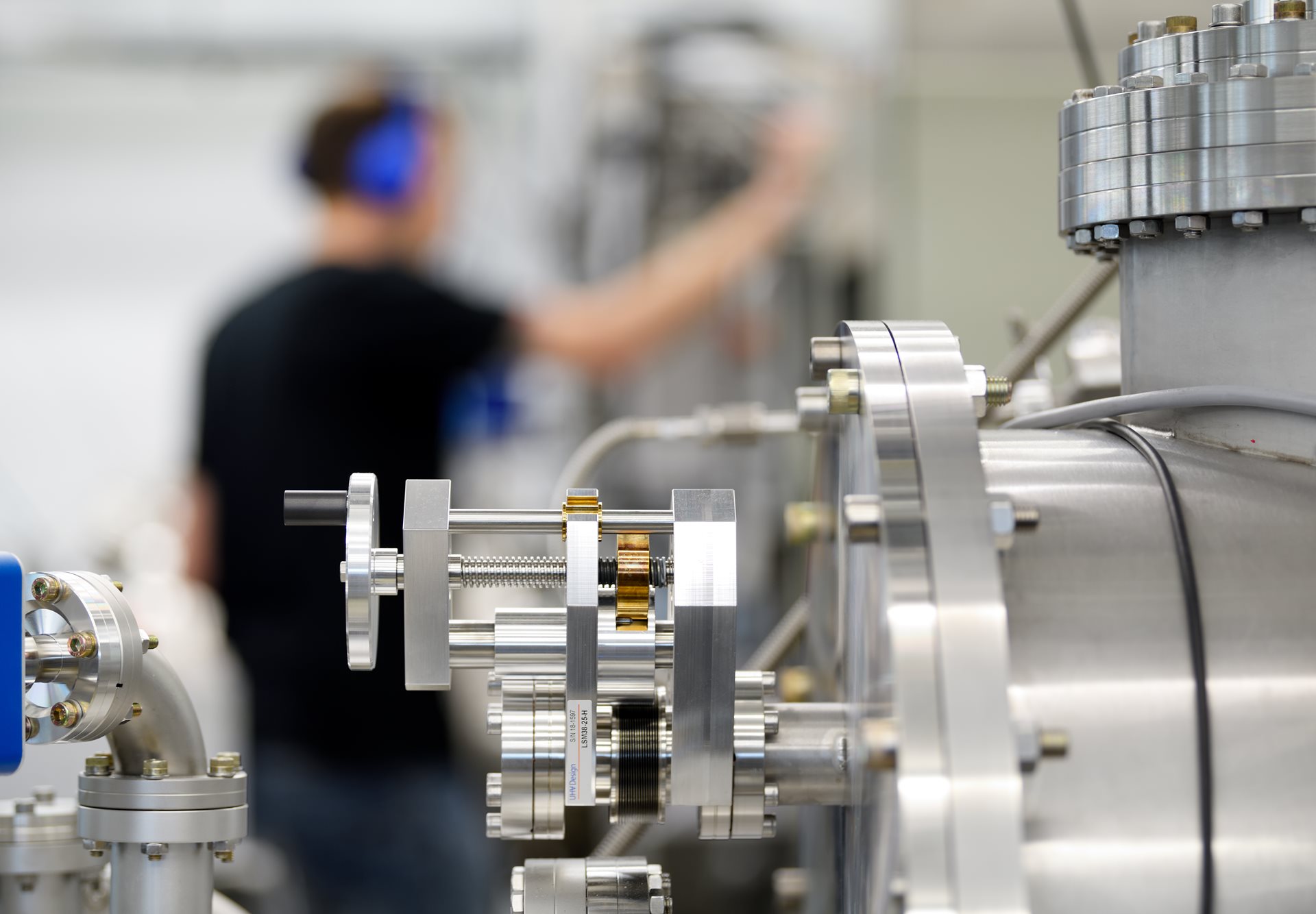

This isn’t your run-of-the-mill mechanical engineering – this is mechanical engineering to the extreme.

As a mechanical engineer at ASML, you become a creative problem-solver that sees your most innovative ideas mature into real operational systems. You'll design, build and test exceptionally high-performance systems.

Create systems that can cope with environments that don't exist anywhere else: high-speed robotics, liquid metals, high temperatures, flammable gases, vacuums, and high-power lasers.

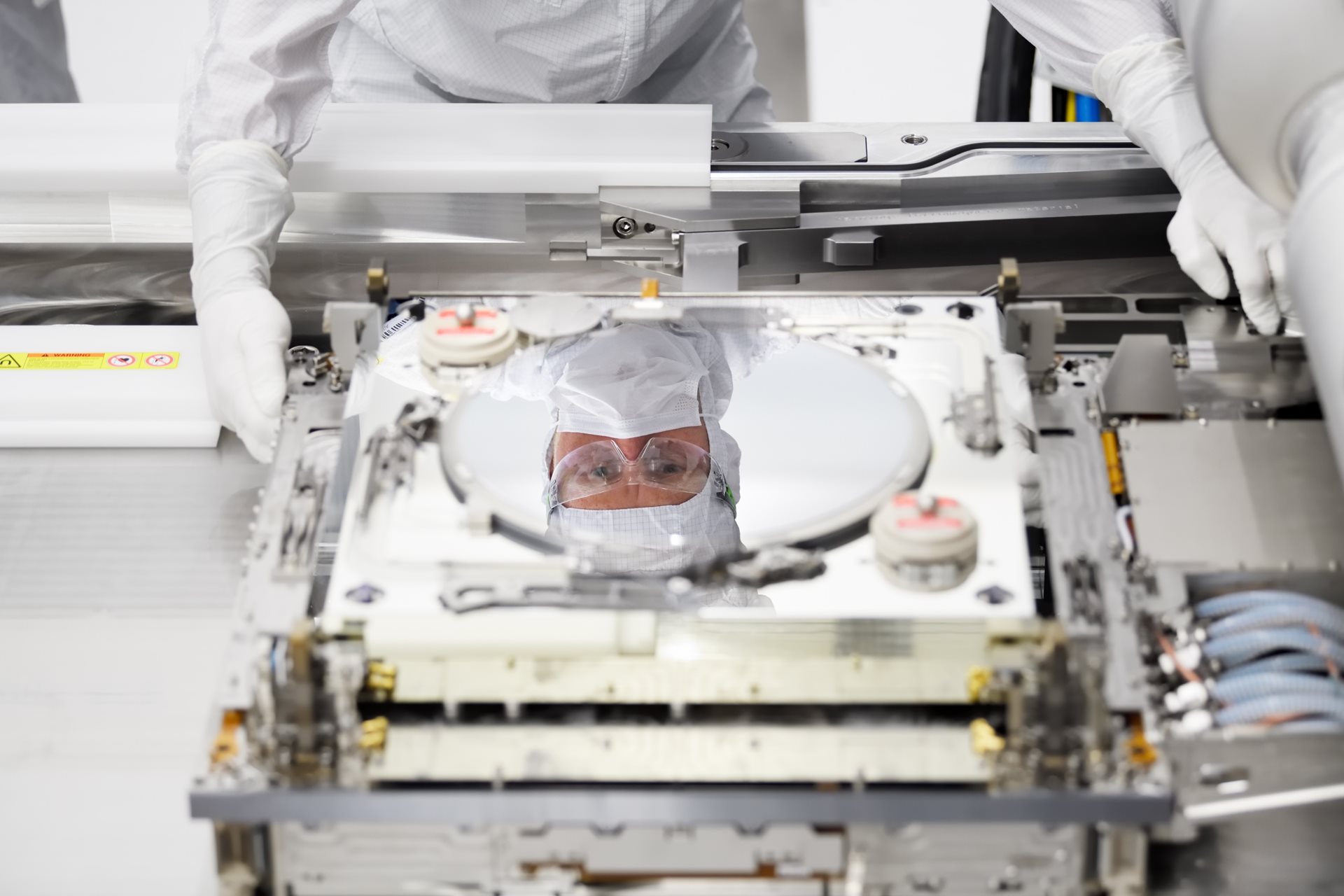

A look at the wafer stage

This is the wafer stage, one of the key modules in our lithography systems that our mechanical engineers work on.

The stage moves two wafer tables simultaneously, each holding a silicon wafer. While one wafer is being exposed to extreme ultraviolet light that contains the chip pattern to be printed, the other is measured by the machine’s metrology sensors to optimize alignment.

The wafer tables move electromagnetically, allowing frictionless acceleration up to 7 g. This is where mechatronics, optics design and metrology (measuring, data processing, and control) come together to deliver the accuracy and speed needed from our lithography systems.

Working on this critical component is just one of the perks of working at ASML as a mechanical engineer – but there is so much more.

Discover all opportunities in mechanical engineering at ASML.

Want to be alerted for new jobs?

Create job alertThe perks of working in mechanical development

Six ASML engineers break down the benefits of working in one of our most critical engineering fields.