Work at the forefront of electrical innovation.

Our state-of-the-art systems are intricate machines with diverse and complex electronics, meaning that the opportunities in electrical engineering at ASML are just as diverse.

Work on analog or digital designs, cabling and layout, sensor electronics, power electronics, motion control or mains distribution system – you have the freedom to work on what you’re passionate about.

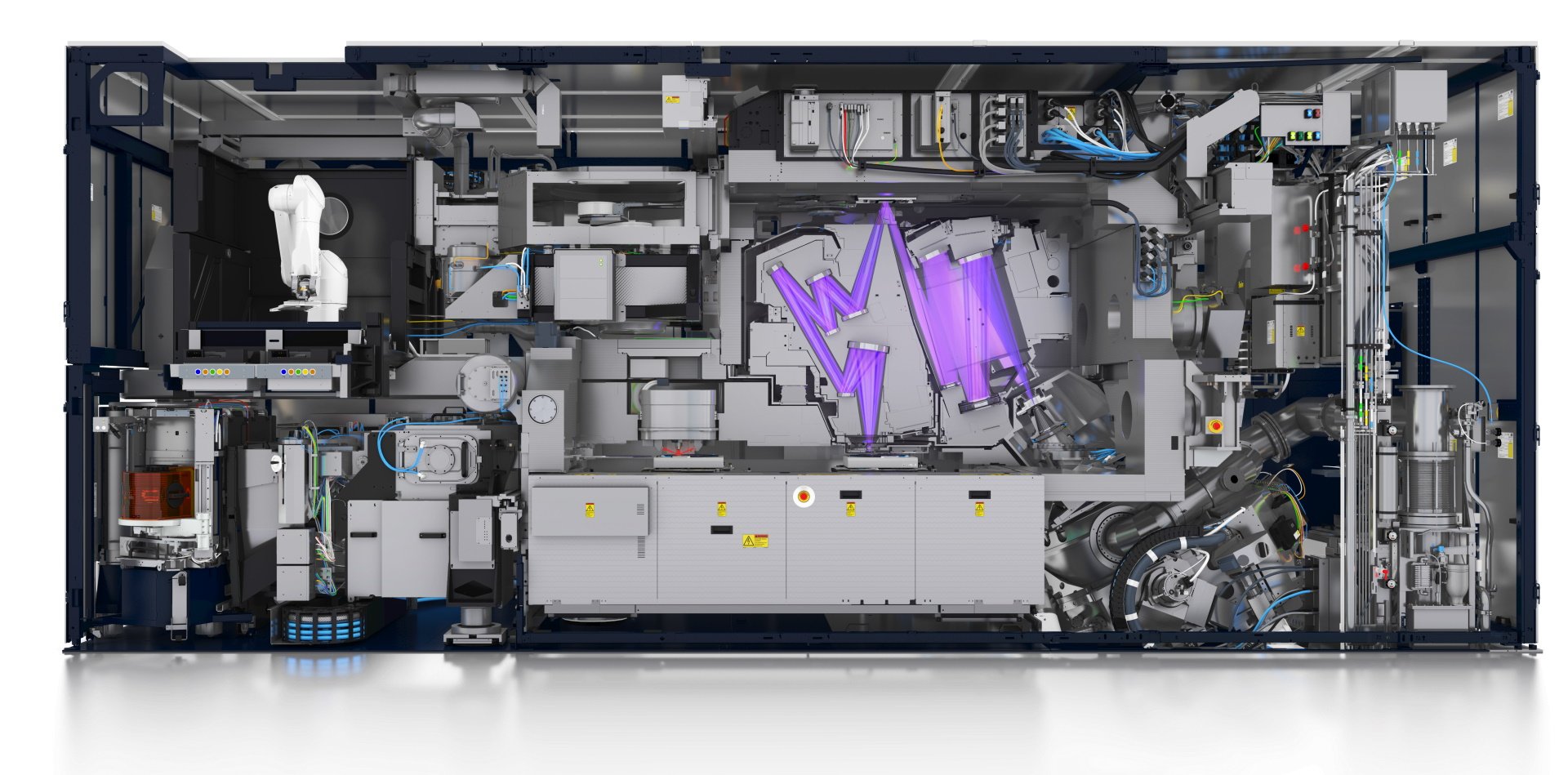

Inside the EUV machine

Analog and digital designs, cabling and layout, sensor electronics, power electronics and motion control all come together in our extreme ultraviolet lithography machines.

It's just one challenging area in which our electrical engineers work. EUV light is generated in the source module and then sent into the illuminator, which controls the light beam. The light reflects off the reticle (the mask containing the pattern that is printed on the chip) and is then focused by the projection optics to ‘expose’ the silicon wafer.

The wafers are mounted on tables in what’s called the 'wafer stage'. The stage moves two wafer tables at the same time, each holding a silicon wafer. While one wafer is being exposed to the light, the other is measured by the machine’s metrology sensors to optimize alignment. The wafer tables move electromagnetically, allowing frictionless acceleration up to 7 g.

Making a difference

Faced with a complex issue, Anya Kish rose to the challenge by turning it into a growth opportunity